Comprehensive Guide to Different Types of Industrial Fuels

Industrial fuels are considered as a crucial element in production processes and generation of energy. They drive mechanical operations in industries, supply heat to any operations requiring it and produce electricity for several industries. Industry capabilities are ever expanding, and as they do so, there is a requirement for energy and a change in the type of fuel capable of providing this energy. This guide will cover all categories of industrial fuel, their application, benefits and drawbacks to assist industries in their fuel selection.

1. Coal

Coal is one of the oldest industrial energy resources or fuels used in energy production processes. For many centuries it has been used as one of the primary sources of energy, especially in the generation of power as well as the heavy industries. They are anthracite, bituminous, sub-bituminous and lignite coals which differ in carbon and energy contents.

Uses

- Electricity Generation: It should be noted that coal is used at power plants to create electricity even in the present days.

- Steel Production: As coke, which is a vital input for the manufacture of steel, coal is indispensable. It is used in blast furnaces, to smelt iron ore.

- Cement Manufacturing: Coal is used in cement industry for firing purposes Cement industry is one of the largest contributors to the market of energy consumption and coal is widely used as a source of energy in cement industries.

Advantages

- Abundant availability: There is an abundance of coal resources nowadays around the globe.

- Cost-effective: It is less expensive relative to many other types of fuel, and, therefore, it is good for industries that require inexpensive energy.

Challenges

- Environmental impact: It also results to a great extent to the emission of CO2, which is a known factor to contribute to global warming.

- Air Pollution: Sulfur dioxide and nitrogen oxides as well as particulate matter produced when fueling coal emit hinders air quality.

2. Natural Gas

Natural gas, which exists mainly in the form of methane, is accepted as one of the cleaner sources of fossil energy because its carbon emissions are less than those of coal and oil. And this type often is widely used in industrial facilities for a number of reasons - the efficiency and versatility of its use.

Uses

- Power Generation: Natural gas is extensively used by many industrial plants and power stations in the generation of electricity.

- Heating: The use of natural gas is evident in industrial buildings as means of heating in boilers, furnaces and kilns.

- Chemical Production: Natural gas is utilized in production of several chemicals for instance ammonia for fertilizers and Methanol for manufacturing plastics.

Advantages

- Low emissions: Natural gas is slightly less carbonized than coal, and has fewer emissions of carbon or airborne pollutants.

- Energy efficiency: It is a higher energy yield for the same amount of fuel than when using coal which is the most common fuel used for generation of electricity.

Challenges

- Dependence on pipelines: (For industries that are far from natural gas supply points) transportation of the fuel can be expensive and a challenge.

- Price Volatility: Market forces and supply and demand are subject to frequent price indifferences and market variation across Middle Eastern geopolitical boundaries.

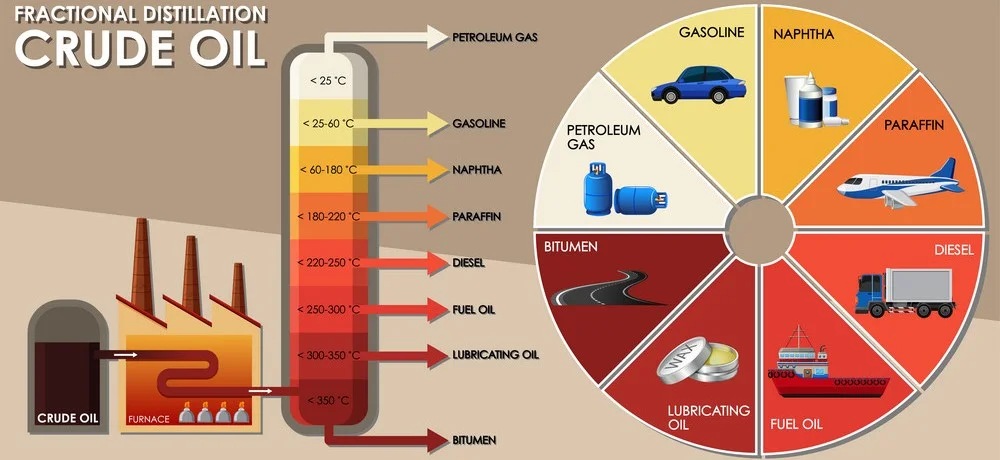

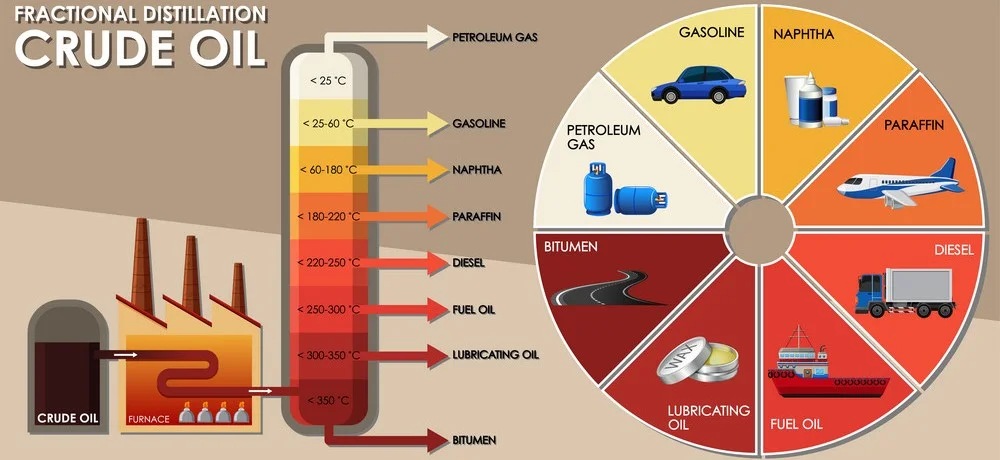

3. Oil and Petroleum Products

Petroleum has remained one of the main industrial products for several decades especially as a source of energy in automobiles, for heating and generation of electricity. Fuels for example diesel, gasoline, kerosene and fuel oil are common inputs to many industrial processes.

Uses

- Transport: Petroleum products inclusive of oil, diesel and gasoline are used in the transport sector in industrial and commercial nature.

- Power generation: Some power plants utilize fuel oil to run in substitution to the use of coal and natural gas.

- Industrial heating: Oil based fuels are traditionally used in most industries for producing heat through boilers and furnaces.

Advantages

- High energy content: The heating power derived from oil is quite high to support the large machinery in industries hence making it suitable as a fuel.

- Versatility: Petroleum products are utilized widely to initiate and operate tools and devices as well as for production of heat and energy.

Challenges

- Environmental concerns: The use of the products through burning causes air pollution as well as emission of greenhouse gases.

- Supply constraints: The product in focus is oil, and this is a known fact that supply of such products is often hampered by geopolitical issues.

4. Biofuels

Biofuel is any fuel generated from biological sources including plants, animal fats, and waste. Storing and harnessing them can be repeatedly done and they are reportedly safer than the traditional source of energy, fossil fuel. Bio fuels include ethanol, biodiesel and biomass Biofuels can also be classified on the basis of source as first, second or third generation.

Uses

- Electricity generation: Biomass power plants use solid organic fuels, including wood pellet and agriculture and forest residues, to generate electricity.

- Transportation: Ethanol and biodiesel are widely used as Bio fuels to gasoline and diesel to be used in automobiles.

- Industrial heating: As sources of heat, woody biomass like wood chips or biogas is employed in industrial boilers.

Advantages

- Renewable: Bio fuels are replaced naturally since they come from agricultural processes, and thus can be regarded as sustainable.

- Lower carbon emissions: When using biofuels for combustion, the CO2 is emitted, but this carbon is regarded as a closed cycle and thus provides biofuels with a competitive advantage.

Challenges

- Land use: The establishment of large- scale biofuel production implies enormous areas of agricultural land important for food production.

- Energy efficiency: It is noteworthy that some biofuels are less energy dense than fossil fuels in some cases; that is unsafe or unreliable for some uses.

5. Hydrogen

Hydrogen is on an upward rise when it comes to the adoption of a clean source of fuel in comparison with fossil-based fuels especially among industries that are embracing change with an aim of minimizing on the emission of excessive CO2. Hydrogen can be utilized in fuel cells as in generation of electricity or in internal combustion engines.

Uses

- Fuel cells: Hydrogen fuel cells are utilized in some industries and transport systems; the only product emitted in electricity generation is water vapor.

- Industrial Processes: Hydrogen can be used in the synthesis of ammonia as well as; in refining of petroleum products, in certain chemical reactions.

- Power generation: Hydrogen can be applied in turbines to generate electricity; this would be a better option to natural gas.

Advantages

- Zero emissions: Hydrogen, when employed in the fuel cells, yields no emissions except water vapor emissions.

- Renewable production: Renewable sources of making hydrogen include through electrolysis, whereby water is split into hydrogen and oxygen, the electricity used being from renewable sources.

Challenges

- Storage and transportation: Hydrogen is highly flammable and does not have a good energy density, time of storage and transportation also add up to it.

- Cost of production: The creation of hydrogen, let alone renewable hydrogen, is costly and demands a unique network of production.

6. Nuclear Fuels

Nuclear energy is derived from nuclear fission in which the new nucleus forms generates heat energy, uranium or thorium are often used. While nuclear power is not a common source of energy in miniature industrial processes it occupies a great importance in large scale power production.

Uses

- Electricity generation: Nuclear power plants remain as a source of electricity supply for a significant fraction of electric power generation.

- Industrial applications: Nuclear power is employed where heat is needed; e.g., in the creation of isotopes for medical utilization.

Advantages

- High energy output: Nuclear fuels give out substantial amounts of energy and are in large measure dependable sources of energy.

- Low emissions: Nuclear energy creates electricity with little contribution to greenhouse gas emission.

Challenges

- Safety concerns: Nuclear power plants are a measure that could be unsafe in regards to safety in case of some accident or radiation leakage.

- Waste disposal: The hazardous waste stays radioactive for thousands of years, and after that, their disposal is still not safe.

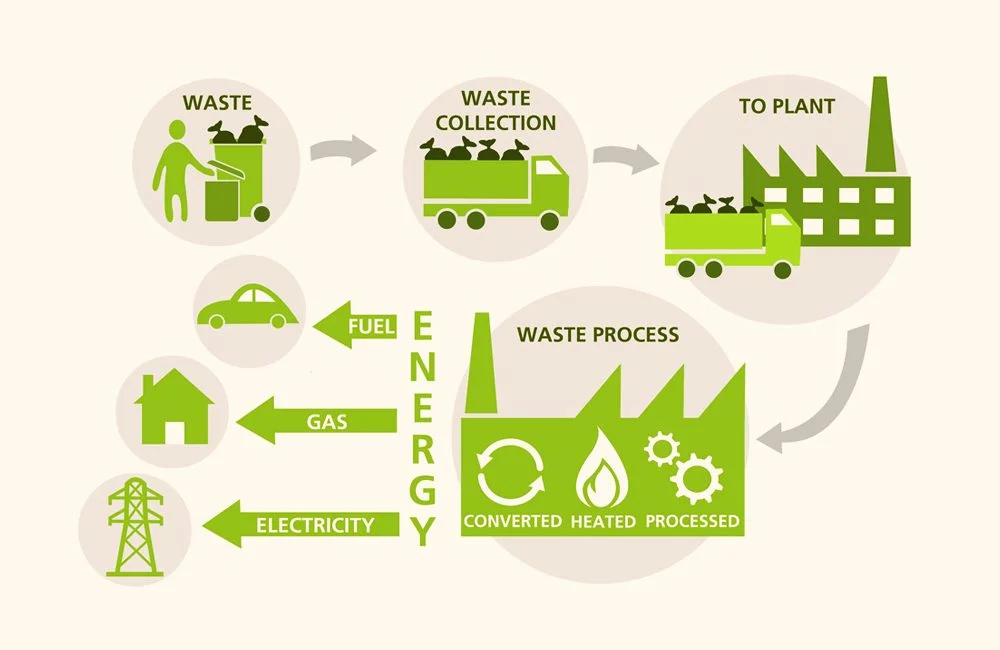

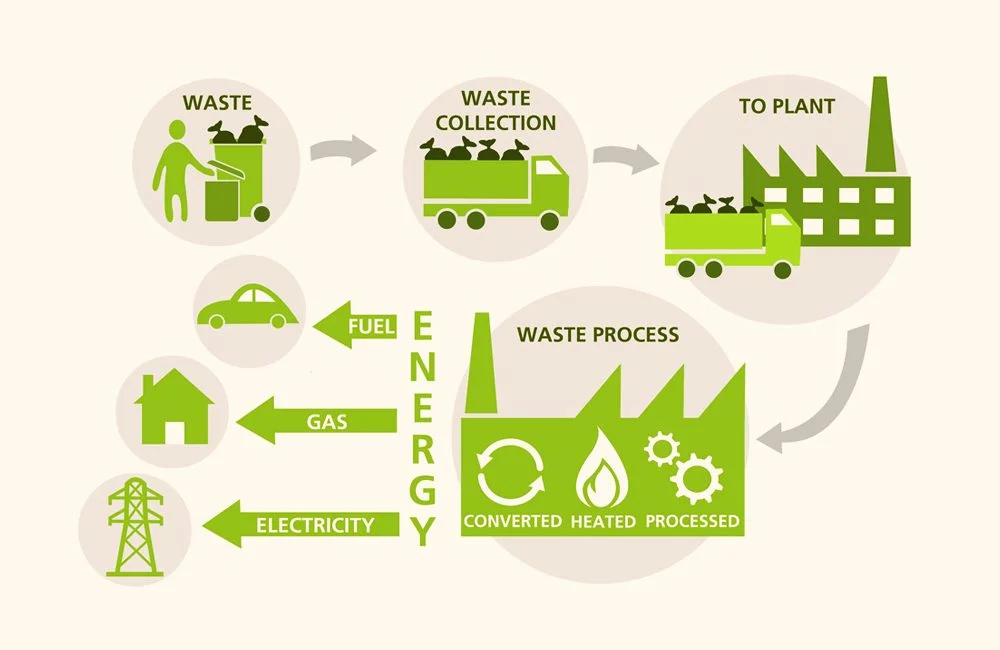

7. Waste-to-Energy (WTE)

Waste-to-energy systems usually refer to processes whereby waste is converted to energy in a usable form such as electricity or heat. It assists in overcoming problems related to waste disposal and concomitantly produces energy.

Uses

- Electricity generation: WTE plants combust waste feed stocks to produce steam which will turbine to generate power.

- Industrial heating: Because waste produced can be converted to energy different industries can use it directly instead of the conventional fuels.

Advantages

- Waste reduction: WTE lowers the amount of waste that ends avoidably in landfills and incinerators.

- Renewable energy source: Theoretically, waste-to-energy is renewable energy if the waste is biodegradable.

Challenges

- Emissions: Some compounds found in waste can combustion’s result from the burning of waste which generates dangerous emissions, such as dioxins and furans.

- Contaminated waste: Some of the waste types may be more dangerous or may contain elements that can be dangerous during the energy conversion of the wastes.

Conclusion

In selecting the industrial fuel, several factors come into play including cost, environmental effects, accessibility and the particular industry application. Industrial fuel remains firmly in the grip of coal and natural gas while biofuels, hydrogen and waste to energy have a higher stake in the future as they are more environmentally friendly. As the need for smaller CO2 emissions comes into play, the use of cleaner, renewable fuel resources is expected, creating a brighter future with high energy efficiency.