Industrial Coal Grades: Which is Best for Your Industry?

10 January, 2026

03 July, 2025

Coal has powered civilizations for centuries, driving industrial revolutions and supplying energy to homes and industries worldwide. Lignite coal, or as it is commonly called, brown coal, occupies a unique position among different varieties of coal. Despite the fact that lignite is regarded as the lowest rank of coal due to its wetness as well as lack of carbon, it has been vital in the power generation sector in some parts of the world, owing to reliability and affordability, besides its massive deposits. This blog will get to the roots of the process of lignite mining, purification, and processing to use it as a stable energy source in the larger coal and lignite landscape.

The lignite refers to the initial phase of coal development. Lignite has experienced the lowest levels of heat and pressure when compared to other types of coal, like bituminous or anthracite. It looks like brownish-black, with a high moisture content (30-60%) and crumbly texture, which helps to notice it in comparison with the coals of higher grades. Lignite, though of relatively lower energy content, is an indispensable commodity to the power plants that are established close to the mining areas since they are cheaper as far as using the lignite locally.

Key Characteristics of Lignite Include:

Color & Texture: Brownish-black and soft, easily broken into small fragments.

Heating Value: Lower calorific value compared to higher grades of coal.

Moisture Content: Exceptionally high, which reduces efficiency but keeps costs low.

Storage Risks: Susceptible to spontaneous combustion if not stored correctly.

Common Use: Primarily in thermal power plants, where it is burned to generate electricity.

The balance of affordability, availability, and ease of mining makes lignite a preferred fuel in countries with large domestic deposits. Factors such as lignite coal price also influence its demand across regional markets.

Lignite mining involves extracting deposits found close to the Earth's surface, making it economically feasible compared to deep coal mining operations.

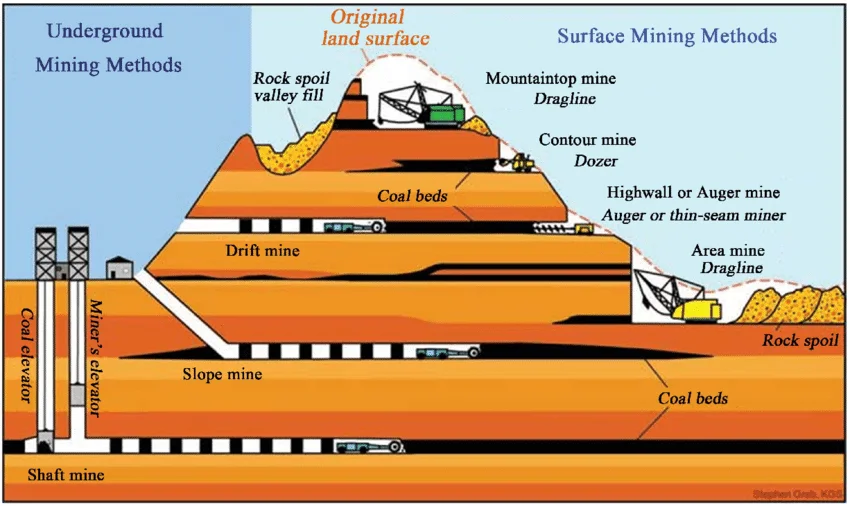

Surface (open-cast or strip) mining is the predominant technique employed for lignite extraction. The lignite reserves are exposed through easy and cheaper mining due to their shallow depth of less than 200 meters underground.

The Detailed Process Includes:

Land Preparation: Before mining can begin, the land area is cleared of trees, shrubs, and topsoil to provide access to the overburden layer.

Overburden Removal: The layers of rocks and soil that cover the coal seams are removed through gigantic earth-moving equipment that includes draglines, bucket-wheel excavators or electric shovels. That is done by careful engineering to make it stable and safe.

Lignite Extraction: After the overburden is stripped away, the lignite seams are carefully removed using hydraulic excavators or bulldozers to minimize wastage and maintain coal quality.

Transportation to Processing Units: The extracted lignite is transported via conveyor belts, dump trucks, or trains to on-site or nearby processing facilities or directly to power plants.

Land Reclamation: The modern coal mining industry is regulated to provide backfilling, replacement of topsoil, and replantation of vulnerable lands so that the affected ecosystem is restored, and the environmental risks are minimized.

Although surface mining predominates lignite coal mining, underground coal mining techniques such as room-and-pillar or longwall underground mining might be employed in some cases in the event the seams prove to be unexpectedly deep, or when surface mining is not possible either because of geographical restraint, environmental impact, or when cost constraints of the surface mine are prohibitive. The lignite is, however, softer, making the mining underground more difficult, thus expensive, which is the reason why this mode is seldom chosen when it comes to lignite.

Lignite remains unusable as raw material after extraction because it is excessively moist and burns erratically. Lignite is then refined and processed, overall in an orderly process, so that it can be used in power stations or any other industry.

Lignite typically arrives from mines in large chunks, unsuitable for efficient combustion. Therefore, it has to be subjected to crushers first, in which it is crushed to smaller, uniform sizes. This makes it easier to handle, drier, and burns consistently in its end-use. Vibrating screens are used after crushing to size lignite, by removing oversized or undersized particles, which can decrease efficiency.

The characteristic feature of lignite is that it contains high amounts of moisture, up to 60 percent in certain cases, and drying becomes a key component of its processing. When lignite is burned when wet, the efficiency significantly reduces and the emissions are higher. Drying involves:

Air Drying: Natural evaporation by leaving lignite exposed to air over time, although this is inefficient on an industrial scale.

Mechanical Drying: Industrial-grade dryers such as rotary or fluidized bed dryers apply heat and air circulation to remove moisture quickly and uniformly.

Advanced Drying (DryFining™): The most innovative technologies, such as DryFining™, have the ability not only to cut off moisture, but also impurities of the fuel such as sulfur and mercury, so that the fuel becomes cleaner and more effective.

Proper drying provides lignite with a better heating value, lowers emissions, and ensures safe storage and transportation, since it minimizes the possibility of spontaneous combustion.

In some regions, lignite is further processed into briquettes, especially for domestic heating applications. The lignite can be ground to a fine powder, dried and pressed into small blocks or briquettes, which are transported, stored and burned easily.

Lignite is also capable of carbonization, or heating without air to combust its volatile matter, converting lignite to a fixed carbon-rich fuel refined to the grade of use in such specific consumptions as in the metallurgical process.

Jay Ganesh Minerals is a trusted name in the market as far as the sourcing of high-quality lignite coal and industrial fuels and industrial minerals is concerned. Established in 2005, the company has been dedicated to bringing quality fuel solutions based in Morbi, Gujarat, India. A company with five proven and refined mining facilities, Jay Ganesh Minerals concentrates on extracting, processing and selling lignite coal and imported Indonesian coal as a source of energy in diverse industrial applications.

Its quality focus on the firm is visible throughout the entire process of mining and purification, packaging, and delivery of fuel products that are reliable and efficient to the clients, meeting the world standards. They already have a wide range of clients like thermal power plants, ceramic industries, gasifiers, and brick manufacturing units, all of whom depend on Jay Ganesh Minerals to get a constant supply of fuel. Moreover, the company is extremely concerned with being environmentally responsible as it employs sustainable ways of mining, restoring land, and maintaining regulatory standards. Such commitment has positioned Jay Ganesh Minerals as the favorite industrial fuel partner in India and abroad.

Lignite has the common characteristic of being sensitive to storage and also subject to spontaneous ignition and thus its use is mostly limited in the vicinity of mining spots. This eliminates the expense of transport, as well as the risk to the environment through extensive transportation of coal.

Major Applications Include:

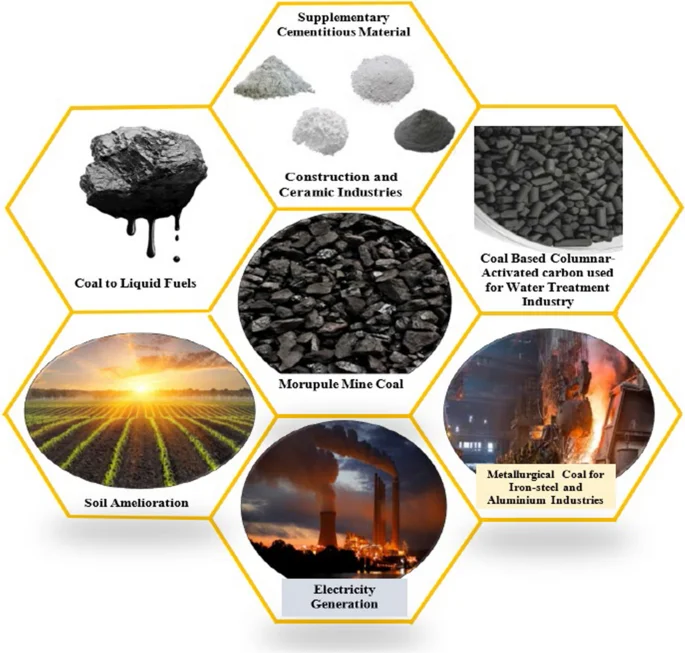

Electricity Generation: The majority of the lignite being dug in the world today is burned in thermal power plants through combustion to generate steam and it in turn powers turbines that produce electricity.

Gasification and Liquefaction: Some industries purify lignite and produce synthetic gases or liquid fuels; they provide alternative energy resources from coal.

Industrial Heating: Lignite in heavy manufacturing industries, such as cement production, paper production, and chemical processing, is used to attain the high temperatures required in their operations.

Residential Heating: Lignite briquettes are a cheap source of fuel used in several nations to heat their homes and cook in. However, with the coming of alternatives that are more eco-friendly, this is becoming less popular.

Burning lignite releases more CO₂, sulfur dioxide (SO₂), nitrogen oxides (NOₓ), and particulate matter as compared to the higher-rank coals. This fact makes lignite a major contributor to air pollution and production of greenhouse gases unless it is controlled by modern emission control devices such as electrostatic precipitators or flue gas desulphurization units.

Lignite processing and mining activities have huge water uses, which are a problem in areas of water shortage. In addition to this, open-pit mining significantly changes landscapes, resulting in habitat loss, erosion, of land disturbances to the ecosystems unless conscious land restoration efforts are imposed after the mining process.

Lignite is very volatile and has high moisture content; it has the risk of spontaneously combusting during storage. Proper stockpile management, moisture control, and fire prevention measures are critical for safety.

In order to make the environment sustainable in the long term, modern mines are under an obligation to ensure land reclamation techniques that involve covering the land with topsoil, planting of vegetation, and reformation of water bodies to restore the geographical landscape to a usable level or natural environment

While lignite remains an important energy source, especially in countries like Germany, India, Russia, and the USA, its environmental drawbacks push industries toward innovation.

Carbon Capture and Storage (CCS): Captures carbon emissions from lignite plants and stores them underground, preventing atmospheric release.

Integrated Gasification Combined Cycle (IGCC): Converts lignite into syngas for cleaner, more efficient energy production.

Fluidized Bed Combustion (FBC): Allows combustion at lower temperatures, reducing NOₓ and SO₂ emissions.

By-products of lignite production are also utilized as building materials in the construction industry to produce cement and bricks, whereas the potential of lignite to be used as high-quality activated carbon and other soil conditioner products is under study, creating new markets for this multi-purpose fuel.

With the first place being taken by oil, lignite coal took the 5th place in the importance list, and it is still a vital energy resource in countries that have it and where the power industry is currently being developed. Although environmental issues cannot be negated, clean technologies together with efficient processing, as well as responsible mining, are already a way forward towards the environmental burden of lignite.

The degree of innovation is the key factor to this in terms of the carbon capture systems, advanced drying technologies, and land rehabilitation, among others, that are applied by the industries and countries to guarantee that this ancient source of energy can co-exist with current sustainability objectives.

Because of its low cost, abundant availability, and suitability for local power generation, particularly where energy infrastructure is still developing.

While possible via carbonization and briquetting, the cost often outweighs the benefits compared to using natural, higher-grade coal or alternative fuels.

Due to the risks of moisture-induced degradation and spontaneous combustion, lignite is rarely exported over long distances.

Lignite's future depends on innovations like CCS, gasification, and blending with renewables to reduce its environmental impact.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected]

|

Mr. RAJESH +91 99130 87000 |

|

Mr. JIGNESH +91 89800 70055 |