Types of Clay Used in Ceramic Industry

03 March, 2026

04 August, 2025

In contemporary industry, refractory products have become essential as long and short term needs in regard to ever-more stable and temperature-resistant materials took place. Ball clay powder forms the core of many of these products, and is a unique industrial clay appreciated due to its combination of plasticity, strength and thermal stability. We will discuss in this blog what exactly is a ball clay powder and why it is becoming a favored refractory raw material in manufacturing.

Ball clay is a very fine-grained clay, highly plastic, with a sedimentary deposit, typically composed of kaolinite, as well as promises of quartz, mica, and organic matter. Its name originates from the old English mining tradition of extracting clay in ball-shaped lumps. Ball clay powder stands out among others because it is light in color and possesses excellent plastic properties, which makes it easy to shape in its wet aspect and has an outstanding amount of dry strength, which is essential to industrial manufacturing and the ceramic industry.

Refractory products are materials designed to resist very high temperatures, abrasion and chemical attack. They find a wide application in the form of kiln lining and linings in furnaces, reactors, and other high-temperature applications. Efficiency and safety across industries, including steel, glass, cement and ceramics, all depend on the durability and life span of such products.

High Plasticity: It is a natural binder, which enhances substantially workability of refractory formulations and allows complex shapes to be formed without cracking.

Binder Strength: The fine particles and organic matter add to better dry and unfired strength lowering the chances of breaking when handled.

Thermal Stability: Ball clay powder also does not break down chemically or structurally at increased temperatures, making it ideal to line kilns and furnaces.

Improving Refractories: Due to the lack of plasticity in many refractory materials, powdered ball clay is added to add the necessary formability and dry strength.

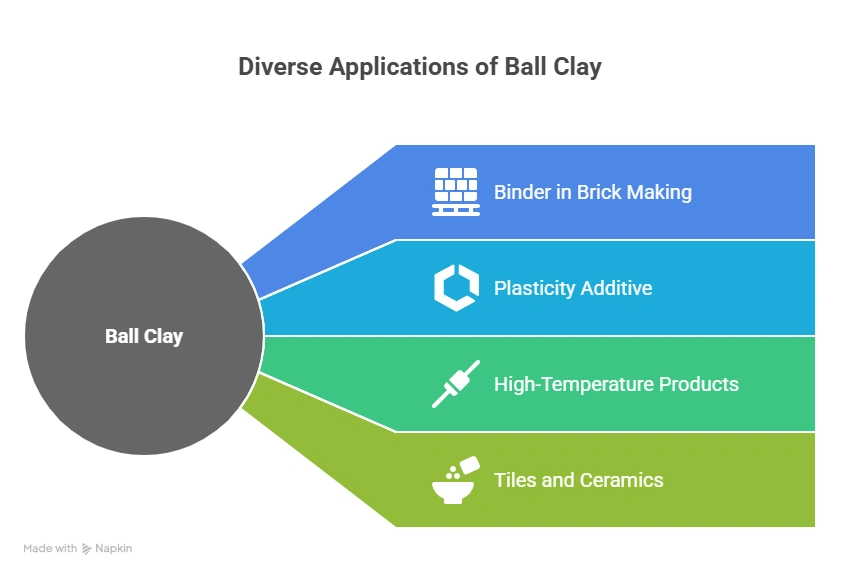

Binder in Brick Making: To make refractory bricks for kilns and furnaces, ball clay powder is compounded with chamottes or other minerals as a binding agent.

Plasticity Additive: Ball clay improves moldability during installation without compromising strength or thermal shock resistance.

Other High-Temperature Products: It’s used in glazes, kiln furniture, and special ceramics requiring durability.

Tiles and Ceramics: Apart from refractories, ball clay is essential in ceramic industry for tiles, sanitaryware, and decorative ceramics due to excellent finishing and firing behavior.

Extraction: Mined from natural deposits.

Drying: Reduces moisture content for handling.

Grinding and Screening: Crushed and screened into fine ball clay powder.

Blending: Mixed with other minerals for custom refractory solutions.

This careful preparation ensures ball clay maintains its plasticity and binding power during production.

Improved Performance: Enhances refractory lifespan under extreme heat.

Better Workability: Allows easy shaping, molding, and extrusion.

Cost-Effective: Offers multifunctional value.

Consistency: Delivers uniform quality, critical for industry-grade refractory components.

When combined with other clay minerals, ball clay powder significantly elevates refractory performance.

Ball clay price varies by location, grade, and market demand. While prices remain competitive, they are affected by energy costs, transport, and mining regulations. Reliable ball clay suppliers offer quality consistency and pricing suited to industrial bulk buyers who demand custom solutions.

Advanced formulations to improve thermal shock resistance.

Eco-friendly sourcing to minimize environmental impact.

Automation in production for precise material blending.

As industries push toward energy efficiency and sustainability, ball clay powder continues evolving as a vital heat-resistant component.

The powder is not only a supplement in the production of refractory materials, but also one of the foundations of the modern refractory industry. Its unmatched plasticity, strength, and thermal resistance make it vital for producing bricks, castables, and structural kiln parts.

As the demand for premium refractory formulations grows, sourcing from reliable ball clay suppliers becomes critical. Jay Ganesh Minerals is a leading provider of top-quality clay minerals such as Ball Clay Powder, Kaolin Clay, Plastic Clay, and Zirconium Silicate.

Whether you need superior plasticity, brightness, or specialized mineral properties—Jay Ganesh Minerals provides solutions tailored to your industrial goals.

Ball clay powder increases plasticity and binding strength, making it easier to form and shape refractory materials while maintaining high thermal resistance.

The clay's ability to withstand high firing temperatures with minimal warping or changes prevents structural failure in harsh industrial settings.

While some minerals like kaolin or fireclay are used, ball clay powder offers a unique mix of plasticity, strength, and fine particle size that can be hard to match.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected]

|

Mr. RAJESH +91 99130 87000 |

|

Mr. JIGNESH +91 89800 70055 |