High Grade WBC Clay Supplier in India

10 August, 2025

07 August, 2025

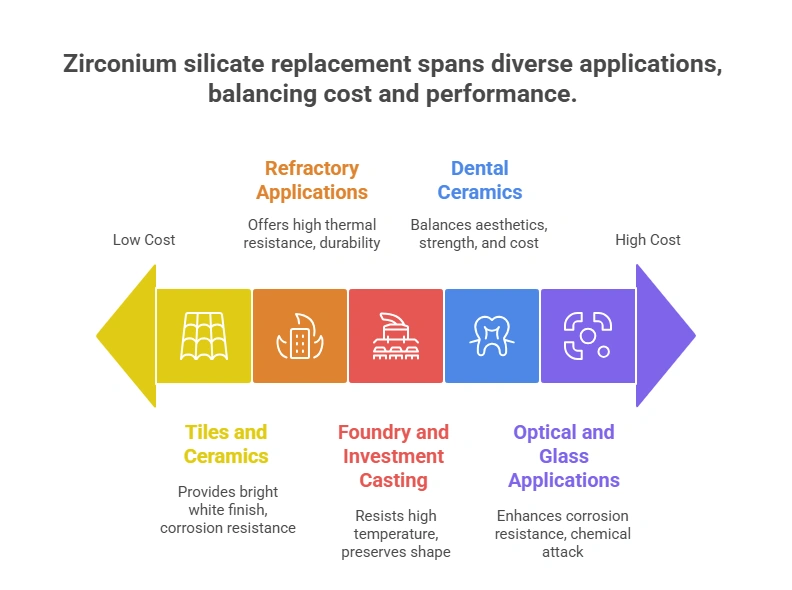

Such materials as zirconium silicate are especially critical in the industries where precision, durability, and temperature resistance are primary aspects. The concept of zirconium replacement has become a tactical factor in the realm of ceramics, refractories and even dental technology as manufacturing matures and there is an enhanced demand of cost effective but highly performing materials.

However, what is zirconium silicate and why are they used as a substitute in the different high tech and conventional industries? This blog is about the fundamental applications in zirconium silicate and how it is transforming the modern day manufacturing industry.

Zirconium silicate ((ZrSiO₄)) is a naturally occurring mineral based on zircon powder. It is chemically a mixture of zirconium, silicon, and oxygen and commonly occurs in a powdered form as zirconium silicate powder or processed opacifier that can be utilized in glazes and coatings.

High melting point (above 2,500°C)

Excellent thermal shock resistance

Low thermal conductivity

Superior chemical stability

These characteristics make it ideal for applications involving extreme heat, abrasion, and chemical exposure.

Zirconium replacement is the replacement of other expensive alternatives or less hardy materials that require to be replaced with zirconium silicate in industrial procedures. Some of the driving forces behind this trend are:

Economic: Zirconium silicate is also much less expensive than the pure zircon or stabilized zirconia, and the former can replace the latter in most applications without loss of quality.

Stability in the supply chain: The natural forms of zirconium occur in only a few areas; using its alternative such as silicate zirconium which is more prevalent keeps the flow stable.

Technical benefits: It is a suitable material in situations where other materials might get damaged or warped by the elevated temperatures.

Zirconium silicate used as a replacement material across several industries, including:

Zirconium silicate is commonly found in ceramic glazes providing a bright white finish, with acidic and basic corrosion resistance. It is frequently an alternative to costly zirconia-based composites without sacrificing desirable opacity and surface strength.

Zirconium silicate is a very good ingredient in molds, kiln linings, and refractory bricks, because of its high thermal resistance. It can be used as a refractory clay substitute to alumina or other expensive oxides in these structures to provide durability at reasonable costs.

In the foundry industry, there are zirconium substitution materials that are used to fabricate molds and cores that resist high temperature when subjected to metal casting. Zirconium silicate has a special value in application as it preserves its shape and is thermal stress-resistant.

Zirconium silicate powder is also emerging into the medical and dental sector as a raw material in dental prosthetics and crown work. It offers a compromise of aesthetics, strength and cost.

In glass, zirconium silicate enhances corrosion resistance and attacks chemicals, and substitutes more expensive additives in high-function glass products.

Better heat resistance than silica

Higher chemical stability than titania

Cost-efficiency compared to pure zirconium oxide

This makes it a versatile and reliable zirconium replacement in many applications that require both performance and economic viability.

Zirconium silicate price depends on the mining expenses, purity level and processing technique. Its price has been more consistent over the last few years compared to pure zircon or zirconia, making it a strategic choice between performance and affordability of manufacturers.

What would this cost? Prices vary between USD 800 and 1,500 per metric ton, depending on quality and location of source. Its availability and market expansion has also increased due to the increased demand in the Asia-Pacific market particularly in India and China.

Consistent sources of zirconium silicate powder specialize in controlling particle size uniformity, purity, and whiteness— which are important in ceramics, paints, industrial coating.

Zirconium silicate is rapidly becoming the material of choice as manufacturers seek performance without a bank break setting. The application of zirconium replacement is increasing in the use in ceramics, refractories, dental and in glass manufacture.

It is an outstanding cost-effective, chemically stable, and heat-resistant mineral which makes it a good alternative in an array of industries due to its low prices. As the market continues to grow and the demand rises, zirconium silicate will become more relevant in manufacturing around the globe.

Jay Ganesh Minerals is one of the trusted zirconium silicate suppliers of a premium-quality product. Jay Ganesh Minerals provides zirconium silicate powder products that are of the superior requirements of ceramics, refractories, and industrial applications, with an emphasis on the consistency of their products, purity and customer satisfaction.

Zirconium silicate offers superior thermal resistance, chemical durability, and mechanical strength. It’s also relatively cost-effective, making it a preferred material in tiles, refractories, and coatings.

It is primarily used as an opacifier to improve the whiteness and brightness of ceramic glazes. It also enhances resistance to acid and wear in high-quality ceramic tiles.

Yes. It replaces more expensive opacifiers like zirconium oxide in many applications, offering similar results in opacity and performance at a lower cost.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected]

|

Mr. RAJESH +91 99130 87000 |

|

Mr. JIGNESH +91 89800 70055 |