What is Plastic Clay? Key Benefits and Industrial Uses

02 January, 2026

15 March, 2025

Ball clay is a highly plastic, fine-grained clay used in various industries, including ceramics, construction, and paper manufacturing. It is a significant material in most applications because its better workability, strength, and firing performance. Although not all ball clay is the same, the key to achieving the best results is choosing high-quality ball clay. The following are the considerations to take when it comes to getting a set of chromosomes.

Ball clay is a fine-grained, highly plastic sedimentary clay primarily composed of kaolinite, mica, and quartz. It is known for its workability, somewhat inferior to kaolin clay whose plastic power is less than it is, because it is less refined. Broadly, Ball clay’s high plasticity and shrinkage properties make it suitable for molding and forming which include ceramics and pottery. It possesses a fine particle size, strong workability, and improved bonding and is used in a plethora of industrial uses it. Nevertheless, the composition of ball clay can differ according to source and impact on color, plasticity and other performance, characteristics. This variability requires careful selection to ensure it meets the specific requirements of different industrial applications.

Choosing a reputable supplier is critical. Reliable suppliers offer consistent quality, provide test results, and meet industry standards. Try to find certifications that ensure the product is of good quality.

Therefore, the impurities such as iron, organic matter, or carbon should be as low as possible in the ball clay with a high quality. Clay that is contaminated may cause poor color or strength, early cracking, or firing defects, and the engineer should take this into consideration.

The useability of ball clay depends on texture. Different clays can have different degrees of plasticity: fine-grained ball clay offers better plasticity compared to inferior facing clay, and there are clays suitable for specific industrial applications especially if the clay is not fine grained. Before purchasing, it’s good to test the texture and verify how it’ll work in your needs.

Whether it is suitable for use depends on the moisture levels in ball clay. If there is excess moisture, you will also have storage issues and if there is not enough moisture, you can have a hard time working with the clay. Moisture content optimum varies by the application.

The behavior of ball clay alterations with the increase in temperatures is different. Some types shrink by a great deal, and others resist thermal expansion better. In ceramics, tiles, and refractory applications, the strength of the clay has to be known under heat.

Although there is an inclination to select the least expensive ball clay alternative, ball clay of lower cost may contain impurities or may not have the same properties. Price with quality balance means better performance and long-term value.

Laboratory tests are recommended so high-quality ball clay is conducted. Common tests include:

For small-scale buyers, on-site tests such as hand-molding, drying, and firing small samples can help assess basic quality.

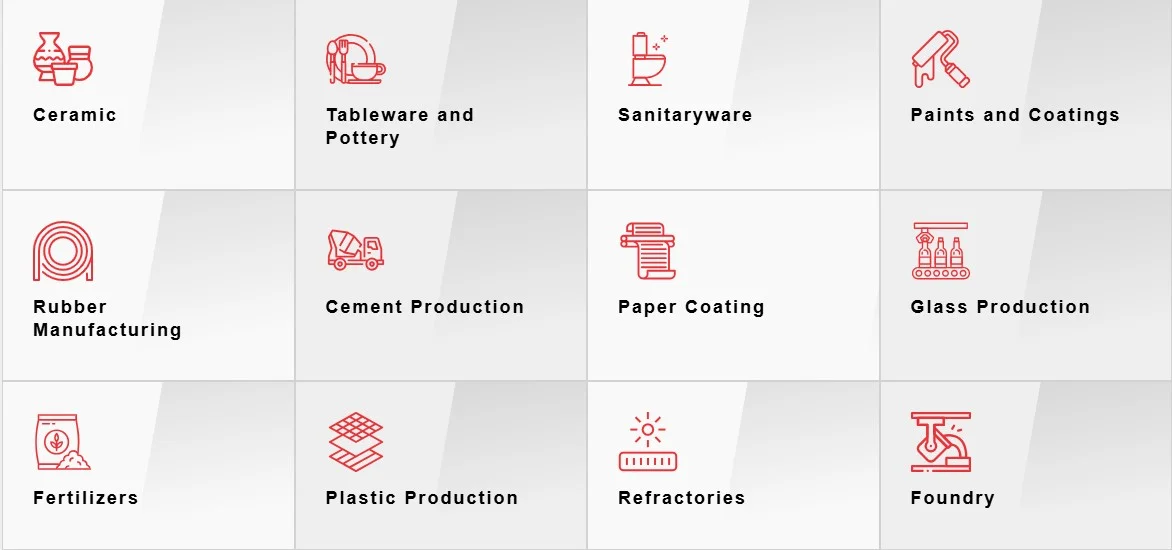

1. Ceramic and Pottery Industry: High plasticity, fine particle size and low impurity content are vital for ceramic and fine pottery production. By using the right ball clay, this improves shaping capabilities, adhesion of glaze to the surface, and firing consistency to yield smooth surfaces with few cracks or warping during firing in a kiln. It is a strong and refined finish material for tableware, sanitaryware and decorative ceramics.

2. Refractory and Construction Use: Ball clay’s thermal resistance, plasticity and binding strength are important in the production of tiles, bricks, sanitaryware and fire-resistant materials. It is almost always mixed with kaolin and usually with other materials in order to improve workability and increase durability under extreme temperatures. The manufacturing of high-quality porcelain tiles, vitrified tiles, and other structural ceramic is made possible by ball clay and all of them can withstand thermal and wear stresses.

3. Hydropower: Ball clay is used to provide potassium for industrial sludge water in conjunction with coal power plant runoff. Papers must be of consistent chemical composition to obtain textural quality and meet the standard of strength and flexibility in the case of polymer products. Furthermore, ball clay is also used in adhesives, sealants and paints because of its fine particle size and binding properties as it promotes uniform dispersion and product stability.

We at Jay Ganesh Minerals are a reputed supplier of high-grade ball clay which is used across all industries, owing to its excellent plasticity, fine particle size and stability in composition. Jay Ganesh Products are committed to providing ball clay that enhances the workability, strength and finish of ceramic products, tiles, sanitaryware cemented carbide in the field of refractory materials. The company is known for meeting diverse requirements of industries and every batch conforms to strict quality standards thus making it a partner of choice to manufacturers of such raw materials.

Choosing high-quality ball clay requires careful evaluation of plasticity, purity, grain size, and firing properties. The best material for your application is what you get when you choose to work with reputable suppliers and conduct the tests required. Knowing these factors is useful when purchasing them for use in ceramics and other construction purposes as well as industrial use.

High-quality ball clay has fine particles, high plasticity, low impurities, and consistent firing characteristics.

Laboratory tests and on-site sample testing help determine purity, texture, and workability.

Yes, ball clay is often blended with kaolin or other clays to achieve desired properties.

It enhances glaze adhesion, improves surface smoothness, and influences fired color.

Reputable suppliers include companies specializing in ceramic and industrial-grade clays, often certified by industry standards.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected]

|

Mr. RAJESH +91 99130 87000 |

|

Mr. JIGNESH +91 89800 70055 |