HS Code for Industrial Mineral & Clay: Export - Import Guide

04 February, 2026

03 February, 2026

Industrial minerals are essential raw materials used across industries such as ceramics, construction, glass, paints, and refractories. However, the performance of these materials depends greatly on their quality and composition. This is where industrial mineral grades become important, as they define purity, particle size, and consistency required for different industrial uses.

Selecting the right mineral grade helps manufacturers achieve better product quality, stable production, and cost efficiency. Using an unsuitable grade can lead to processing issues, higher waste, or inconsistent results. Understanding mineral grades allows industries to choose materials that match their technical requirements and industry standards.

Industrial minerals are naturally occurring, non-metallic materials used in manufacturing and construction processes. Unlike metallic minerals, they are valued for their physical and chemical properties rather than for metal extraction. Common industrial minerals include feldspar, quartz, ball clay, limestone, and kaolin, each serving specific functional roles in industrial applications.

These minerals are widely used as fillers, fluxes, binders, and structural components across industries. Their performance depends on factors such as purity, hardness, particle size, and thermal stability. Because different industries require different properties, industrial minerals are processed and supplied in multiple grades to meet specific application needs.

Selecting the right industrial mineral grades is crucial for any industry. Different applications demand different mineral properties, and using an unsuitable grade can lead to inefficiencies, higher costs, or even product failures. Proper mineral grade classification ensures that manufacturers get materials tailored to their specific needs.

By classifying minerals accurately, industries can maintain consistency, meet quality standards, and optimize performance. It also helps in aligning mineral properties with the intended industrial processes, ensuring smooth production and reliable outcomes.

Ensures the right industrial mineral grades are used for specific applications

Improves product quality and consistency across production batches

Helps industries choose suitable industrial grade minerals based on purity and performance

Reduces equipment wear, processing issues, and material wastage

Supports compliance with required mineral grade standards

Optimizes production costs by avoiding over- or under-specified grades

Aligns material properties with industry-specific performance needs

The mineral grading system is a structured method used to evaluate and categorize industrial minerals based on their quality and performance characteristics. This system helps industries select the most suitable industrial mineral grades for their specific applications while maintaining consistency and compliance.

Chemical purity: Determines the percentage of the main mineral content and acceptable impurity limits. Higher purity grades are required for sensitive industrial applications.

Physical properties: Includes hardness, brightness, density, and whiteness, which directly affect processing efficiency and final product quality.

Particle size distribution: Controls how minerals perform during mixing, coating, or molding processes. Uniform particle size improves consistency and surface finish.

Moisture content: Low and controlled moisture levels are essential to prevent clumping, storage issues, and processing inefficiencies.

Industry-specific testing and certifications: Minerals are tested according to application needs and verified against recognized mineral grade standards to ensure reliability and performance.

Industrial minerals are available in different grades to meet the diverse needs of various industries. Each grade is defined by its purity level, processing method, and intended application.

Industrial grade minerals are naturally processed materials suitable for high-volume industrial use where moderate purity levels are acceptable.

Typical applications include:

Construction materials

Cement manufacturing

Ceramics and tiles

Glass production

Key characteristics:

Controlled but allowable impurity levels

Stable chemical composition

Cost-effective for bulk industrial applications

Suitable for processes that do not require ultra-high purity

Semi-purified grades undergo additional processing to improve performance and consistency. These enhancements make them suitable for more specialized applications.

How processing enhances usability:

Improved particle size control

Reduced impurities

Better dispersion and surface quality

Common applications:

Paints and coatings

Plastics and polymers

Rubber products

Adhesives and sealants

High-purity grades are refined to meet strict mineral grade standards, ensuring minimal impurities and precise performance.

Why high-purity minerals matter:

Essential for sensitive manufacturing processes

Ensures consistent chemical and physical properties

Typical applications include:

Specialty ceramics

Advanced glass manufacturing

Chemical and pharmaceutical industries

High-performance industrial formulations

These industrial mineral grades allow manufacturers to choose materials that align precisely with their technical and performance requirements.

Mineral grade standards provide a common framework to ensure quality, safety, and performance across industrial applications. These standards help manufacturers and buyers identify reliable industrial mineral grades that meet specific technical and regulatory requirements.

International and regional bodies define acceptable purity, physical properties, and testing methods

Standards vary based on industry, application, and geographic market

Regional norms ensure minerals meet local safety and environmental regulations

ISO standards focus on quality management, consistency, and process control

ASTM standards define testing methods and material specifications

Industry-specific benchmarks address application-based performance needs

Ensures product reliability and consistent performance

Simplifies approval for exports and cross-border trade

Meets OEM quality requirements and audit expectations

Builds trust with global buyers and long-term partners

Adhering to recognized mineral grade standards is essential for industries aiming for scalable production and international market acceptance.

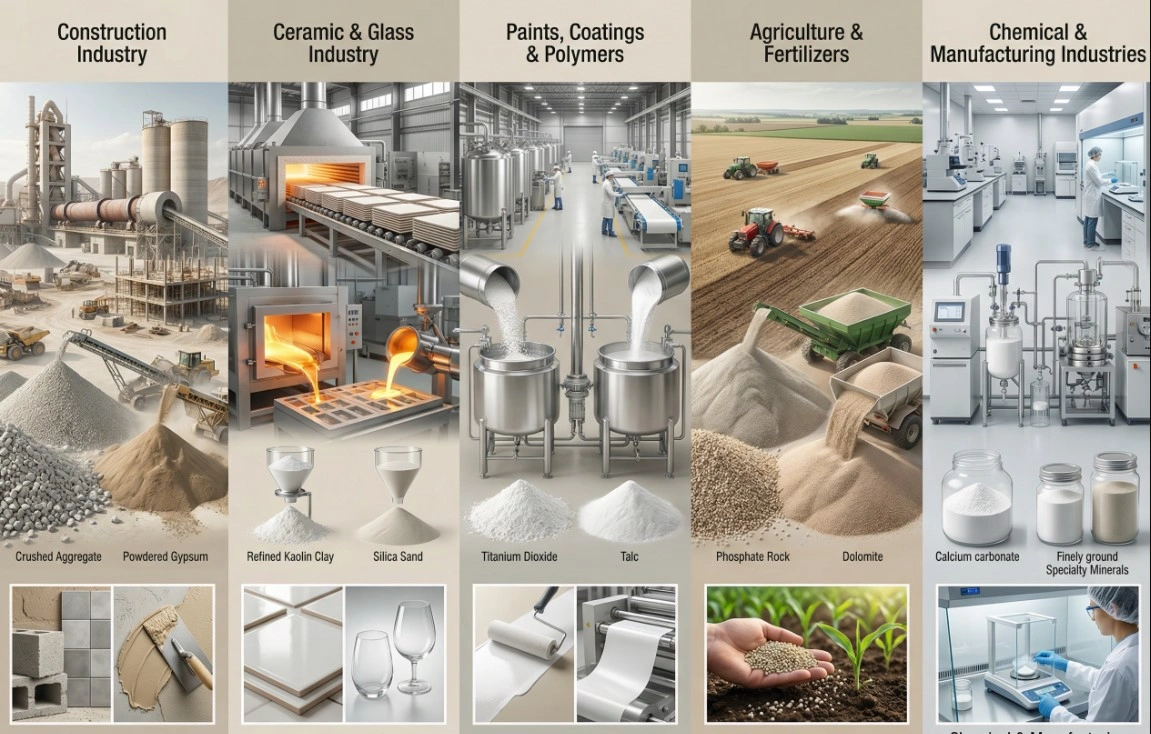

Different industries rely on specific industrial mineral grades based on performance, safety, and regulatory needs. Below is an application-wise overview to help understand how mineral selection varies across sectors.

Industrial minerals are essential raw materials in cement, concrete, tiles, wall putty, and other construction products. These minerals contribute to strength, workability, and surface finish.

Preferred mineral grades:

Standard industrial grade minerals with controlled impurity levels

Consistent particle size for smooth application and strength

Minerals that enhance durability, binding, and surface finish

These grades are ideal for large-scale construction projects where volume and reliability are key.

The ceramic and glass industry requires minerals with higher precision due to the sensitivity of firing and melting processes.

Key requirements include:

High mineral purity to prevent defects

Precise particle size distribution for uniform melting and shaping

Suitable mineral grades for industry:

Processed or high-purity grades

Minerals that support thermal stability and consistent coloration

In paints, coatings, and polymer formulations, minerals influence appearance, texture, and durability.

Important factors:

High brightness and whiteness

Excellent dispersion within formulations

Recommended mineral grades:

Semi-purified and finely processed grades

Minerals that improve opacity, smoothness, and durability

Industrial minerals are widely used in agriculture for soil conditioning, nutrient management, and pH control.

Common applications:

Soil conditioning

pH balance and nutrient support

Key considerations:

Safe and compliant mineral grades for industry

Adherence to agricultural safety and environmental regulations

Chemical and manufacturing sectors demand minerals with precise specifications to maintain process stability.

Specialized requirements include:

Strict control over chemical composition

Low impurity tolerance

Performance expectations:

Consistent quality across batches

Minerals that meet specific process and formulation needs

Selecting the right industrial mineral grades ensures optimal performance and long-term reliability across all industrial applications.

Choosing the right industrial mineral grades starts with understanding the technical needs of your process. Key factors include chemical composition, purity levels, particle size distribution, moisture content, and physical strength. These characteristics determine how the mineral behaves during mixing, forming, heating, or application.

It is also important to consider processing conditions such as temperature, pressure, and equipment compatibility. A mineral grade that works well in one production setup may not perform the same way in another.

Every industry uses minerals differently, which makes matching grade properties to end use essential. For example, ceramics may require controlled flux behavior, while construction materials focus on strength and stability. Selecting grades based on actual performance needs helps avoid defects and processing inefficiencies.

Proper alignment between mineral properties and application requirements improves product consistency and reduces waste. This approach ensures that the selected grade delivers reliable results throughout production.

Higher mineral grades often come with higher costs, but they are not always necessary. Choosing a grade that exceeds application requirements can increase expenses without adding value. On the other hand, using a lower grade to reduce costs may lead to quality issues or higher rejection rates.

The right balance between cost and performance helps manufacturers maintain quality while controlling production expenses. Industrial grade minerals often provide this balance for many applications.

Consistency is just as important as grade selection. Reliable suppliers ensure uniform quality across batches, reducing variations in production. Long-term supply stability also protects manufacturers from sudden quality shifts or shortages.

Selecting mineral grades from trusted sources supports predictable performance, smoother operations, and long-term industrial success.

One of the most common mistakes is selecting mineral grades purely on cost. While lower-priced materials may seem attractive, they often come with higher impurity levels or inconsistent quality. This can lead to production issues, higher rejection rates, and increased overall costs.

A slightly higher investment in the right industrial mineral grades often results in better performance and fewer operational problems.

Consistency is critical in industrial applications. Variations in particle size, moisture content, or chemical composition can disrupt manufacturing processes. Ignoring consistency can cause uneven results, equipment issues, or product defects.

Reliable mineral grading ensures stable performance across multiple production batches.

Each industry has unique technical demands. Using a general-grade mineral without considering application-specific needs can lead to poor results. For example, minerals suitable for construction may not work well in ceramics or glass production.

Understanding mineral grades for industry helps manufacturers choose materials tailored to their specific processes.

Failing to confirm the actual mineral grade classification is another common mistake. Without proper testing reports or documentation, there is no guarantee that the supplied material meets required standards.

Verifying the mineral grading system and quality benchmarks ensures that the selected grade delivers reliable and consistent performance.

Choosing a dependable supplier like Jayganesh Minerals is critical for industries that rely on high-quality industrial mineral grades. The right supplier ensures material consistency, quality, and compliance, which directly impacts production efficiency and product performance.

Experience & Quality Control: Suppliers with years of expertise understand mineral grade standards and ensure every batch meets purity, particle size, and performance requirements.

Consistent Sourcing & Processing: Reliable sourcing and controlled processing guarantee uniformity across batches, preventing production issues and reducing wastage.

Transparency & Documentation: Comprehensive test reports, certifications, and traceability documents simplify compliance with industry regulations and export standards.

Technical Support & Guidance: Experienced suppliers provide advice on selecting the correct mineral grade for specific applications, helping manufacturers optimize processes.

Long-Term Reliability: Partnering with a trusted supplier ensures uninterrupted supply, stable pricing, and a strong foundation for scaling industrial operations.

With Jayganesh Minerals, industries gain a partner that combines quality, expertise, and transparency to support their production goals with confidence.

Selecting the right industrial mineral grades is crucial for ensuring product quality, operational efficiency, and compliance across industries. The correct grade impacts durability, performance, and cost-effectiveness in applications ranging from construction and ceramics to chemicals and agriculture.

High-quality minerals, combined with expert supplier support like that offered by Jayganesh Minerals help manufacturers achieve consistent results, maintain standards, and optimize production processes.

Before finalizing any mineral grade, it is always recommended to consult experts and review test reports, certifications, and supplier guidance. This ensures the minerals chosen perfectly match your industry needs and long-term production goals.

Industrial mineral grades define mineral quality and properties to ensure consistent performance in manufacturing and construction applications.

Mineral grade standards control purity and consistency, helping reduce defects and maintain stable product quality.

Industrial grades focus on functional performance and cost efficiency, while ceramic grades require higher purity for firing and surface quality.

Select a grade by matching mineral properties with application requirements, processing conditions, and budget.

Mineral grading ensures reliable performance, process stability, and consistent production quality.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected]

|

Mr. RAJESH +91 99130 87000 |

|

Mr. JIGNESH +91 89800 70055 |