Types of Clay Used in Ceramic Industry

03 March, 2026

03 November, 2025

Packaging of industrial minerals to export is an important issue that maintains the integrity of materials, avoids contamination, and compliance with regulations when shipping these products internationally. Regardless of whether they are bulk minerals, sensitive powders, or dangerous goods, the best packaging options not only cushion the products, but they also simplify logistics and boost customer satisfaction. This guide provides details about the nature of export packaging, materials, best practices, and compliance requirements and tips to offer answers to key questions in the industry.

Industrial minerals are susceptible to wetness, fracturing, pollution and governmental inspection on transit. Proper packaging ensures that the minerals are safe, retains the chemical composition, avoids being exposed to the environment, and that it resists heat and lasts long. Correct packaging is what will make the difference between a smooth shipment and shipment returns or product deterioration.

When preparing industrial minerals for export, several factors must be taken into account:

Nature of the Mineral: Different minerals have varying sensitivities to environmental conditions.

Mode of Transport: The mode of transport can be either by sea, air or land, each with its own demands and packaging needs.

Destination Regulations: Destination countries can have certain standards and regulations that they would like to be followed.

Handling and Storage Conditions: It is important to consider the way the product will be handled and stored when transporting it to avoid damage.

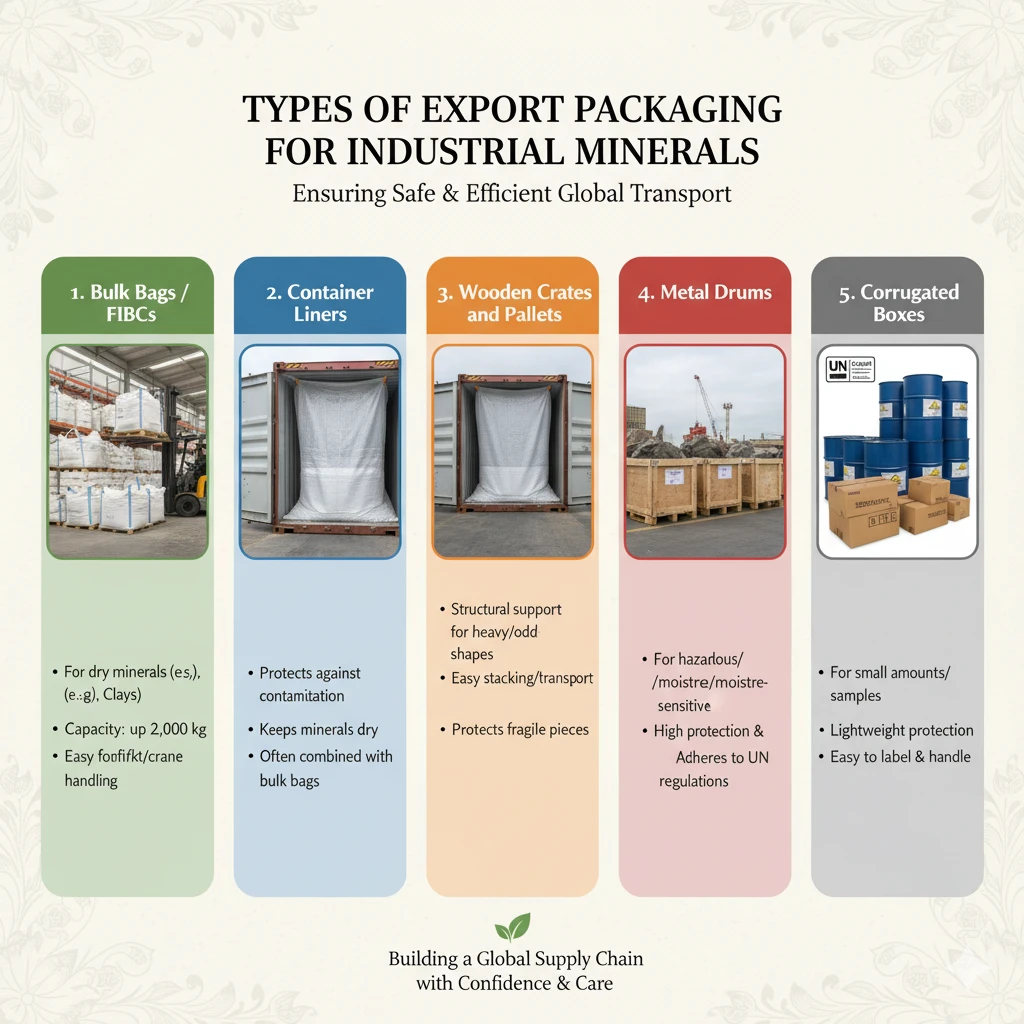

Selecting the right packaging type is essential for the safe transportation of industrial minerals. Common packaging solutions include:

1. Bulk Bags / FIBCs (Flexible Intermediate Bulk Containers): These are suitable in handling dry minerals such as clay like Ball Clay, Kaolin Clay, Plastic Clay, Semi Plastic Clay, White Clay, and Zirconium Silicate they are capable of carrying a mass of 2,000 kg and are simple to operate with forklifts or cranes.

2. Container Liners: Container liners are used in shipping containers to avoid contamination and to keep minerals dry. They have a tendency to be mixed with bulk bags in order to provide protection.

3. Wooden Crates and Pallets: Crates provide the structural support of heavy or not-rectangular minerals, whereas pallets make it easier to stack and transport the minerals.

4. Metal Drums: The metal drums are applicable in the case of hazardous or moisture sensitive minerals and they offer high protection as well as adhere to the UN requirements of transporting hazardous materials.

5. Corrugated Boxes: Small amounts or samples will use corrugated heavy duty boxes which offer light weight protection and are convenient to label, stack and carry.

Choosing the correct packaging material depends on several factors:

Material Compatibility: Minerals are to be packed in materials that are not reactive towards them. As an example, moisture-sensitive minerals must be packed in a moisture-barrier.

Weight Considerations: The heavy minerals require strong reinforced materials such as the FIBCs or metal drums to avoid burst in case of handling.

Moisture Sensitivity: Certain minerals are able to take up moisture and lose quality e.g. gypsum or clay. Desiccant, liner or barrier films packaging is necessary.

Transportation Mode: Sea transportation can bring more humidity to the cargo whereas air transportation requires less weight to be carried. Think about the environmental circumstances and the transportation method and then choose a packing.

Budget Constraints: Although the use of high quality materials is the most protective, it might be expensive. Weigh the cost versus risk so as to make a reasonable trade-off favoring the cargo protection and not spending excessively.

International shipping of industrial minerals requires strict adherence to compliance standards:

ISPM 15 Wood Packaging Requirements: Wooden pallets and crates made of wood have to be heat-treated or fumigated to avoid infestation of pests.

UN Certification for Hazardous Materials: Hazardous materials should be in line with the UN requirements of packaging so that they can be transported safely.

ISO Standards: ISO compliant packaging guarantees standardization, quality and consistency in the manipulation of the industrial materials.

Country-Specific Regulations: A country that imports might have rules that are extra like specific labelling, testing or permits.

Documentation Requirements: It is essential to have proper export documents, such as packing lists, certificates of origin, compliance certificates to prevent wastage of time and fines in the customs.

Moisture is one of the primary threats to industrial minerals during shipping. Effective strategies include:

Desiccant Solutions: Silica gel or clay-based desiccants absorb moisture inside bags or containers.

Barrier Films and Liners: Polyethylene liners or multi-layer barrier films prevent the ingress of humidity and water on the minerals.

VCI Packaging: Volatile Corrosion Inhibitor (VCI) packaging helps protect the rust or even chemical corrosion of delicate minerals.

Container Desiccants: Sometimes huge containers demand additional desiccants to manage the ambient moisture over a long ocean journey.

Climate Control: The Containers are temperature and humidity controlled that offer best conditions to sensitive minerals especially when it is going over long distance.

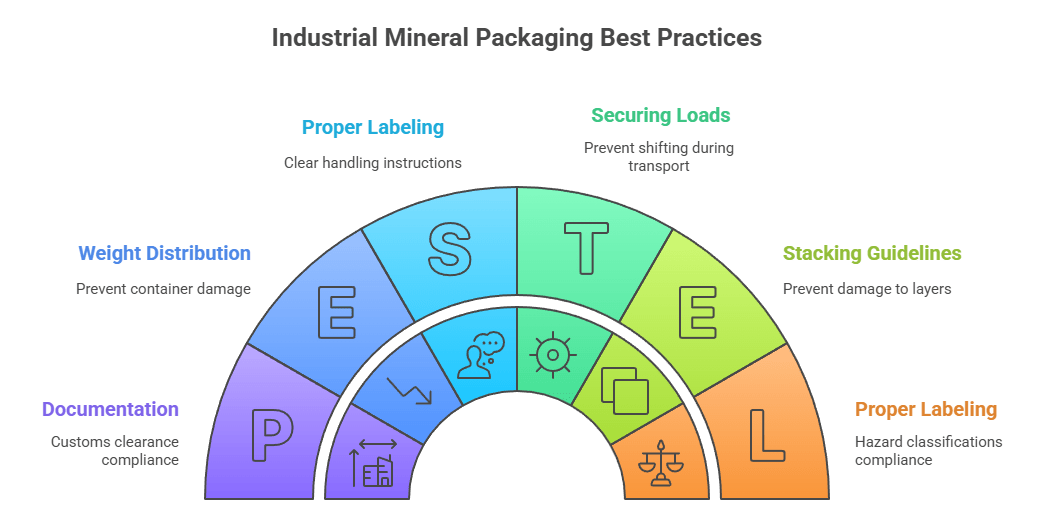

To ensure safe and compliant export, follow these best practices:

Proper Labeling: Clearly indicate contents, weight, handling instructions, and hazard classifications.

Securing Loads: Use straps, nets, or shrink wrap to prevent shifting during transport.

Stacking Guidelines: Avoid excessive stacking to prevent damage to lower layers; follow container-specific weight limits.

Weight Distribution: Distribute heavy minerals evenly to prevent tipping or container damage.

Documentation: Maintain complete, accurate documentation for customs clearance and compliance verification.

Exporters often make avoidable errors that compromise mineral quality:

Inadequate Moisture Protection: Leads to clumping, degradation, or contamination.

Non-Compliant Wood Packaging: Wooden crates without ISPM 15 treatment may be rejected at customs.

Poor Load Securing: Shifting cargo can damage minerals or containers.

Incorrect Labeling: Mislabeling can lead to fines, shipment delays, or safety hazards.

Missing Documentation: Lack of proper paperwork can cause customs clearance issues.

Effective export packaging for industrial minerals is not just about meeting standards it’s about preserving quality, ensuring safety, and reinforcing your reputation in global markets. From choosing the right packaging materials and protective layers to complying with international regulations, each step plays a critical role in guaranteeing that your product arrives in perfect condition and your customers stay satisfied.

At Jay Ganesh Minerals, we've seen firsthand how superior packing and logistics practices make a difference whether it’s delicate clays like kaolin and ball clay, or robust materials like zirconium silicate and industrial fuels. We believe that excellence in mineral extraction must be matched by excellence in packaging, transport, and customer service.

FIBC (Flexible Intermediate Bulk Containers) or jumbo bags are most common for their strength, weather resistance, and efficiency handling large quantities.

Accurate labeling with chemical composition, handling instructions, and international symbols reduces misrouting, mishandling, and helps meet regulatory standards.

Depending on the mineral type, they may require moisture barriers, antistatic liners, UV-resistant covers, or temperature-controlled storage and transit.

Yes. Recyclable packaging, reusable FIBCs, and minimal use of non-biodegradable material are encouraged to reduce environmental impact.

Proper packaging reduces losses and claims, improves stacking and space utilization, and optimizes container loading ultimately lowering total logistics expenses.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected]

|

Mr. RAJESH +91 99130 87000 |

|

Mr. JIGNESH +91 89800 70055 |