Types of Clay Used in Ceramic Industry

03 March, 2026

05 November, 2025

The choice of the appropriate form of materials is a critical factor that might affect industries in the agricultural sector to the chemical manufacturing industry. Suppose sulfur is required to make fertilizer or feldspar to make ceramics - which should it be granular or lump can make a huge difference in efficiency, cost, and quality of the product. The granular materials are usually tiny and easy-flowing and promise to be easy to handle and dissolve faster. Lumps, in their turn, are bigger and firmer, which is convenient in order to carry them in large quantities and be stable over time. The correct choice will provide an easier process of material handling, perfect processing of the powder, and better industrial performance.

In this post, we’ll compare granular and lumps based on several critical criteria: physical properties, industry-specific applications, cost, and what form can bring operational success. Now let us take a plunge to know what kind of material form is best suited in your industrial requirements.

Granular materials are made out of small particles that are generally in the range of 0.2 mm to 4.0 mm; such as granular sulfur, fertilizers, feldspar, and industrial additives. These materials are characterized by high flowability and hence are suitable in automated processes and accuracy in application. They are made by means of spray granulation (molten material is sprayed into drums to create homogenous grains), mechanical crushing, or mixing.

Industries such as agriculture have applied granular form of sulfur in amending soils and efficient application of fertilizers; chemicals and plastics have applied the granular format in mixing and dosing. Grain sizes have a large surface to volume ratio, which means they dissolve and react very quickly in different areas such as pharmaceuticals and chemical processing.

Unlike granular, lump materials have significantly larger particle sizes a few centimeters in diameter, have irregular shapes, and a strong structure. Examples are lump sulfur, mined feldspar and some bulk minerals. The lumps are often mined or extracted and then hardly refined.

The industrial applications focus on bulk applications: Lumps are easily handled with forklifts, and they are appropriate to long-term storage, and they are frequently applied where aggregated materials are better: in large-scale chemical manufacturing, oil refining or bulk fertilizer manufacturing. The lump forming mechanism includes the solidification of liquid mass in bulk, or the separation of large pieces of materials in the natural reserves. This makes them easier to handle and protects them during bulk storage due to their durability and less dust production.

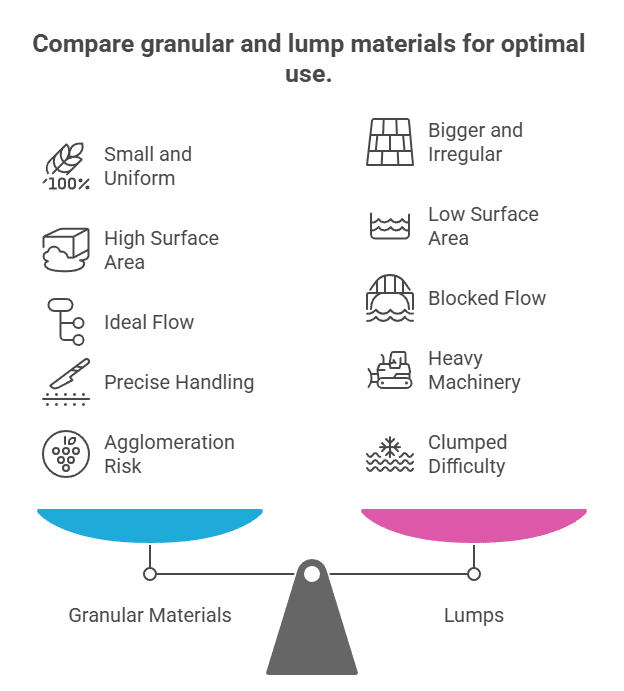

Let’s break down the major contrasts:

Physical Properties: Granular materials are small, uniform, and free flowing; lumps are bigger, irregular, and usually have to be handled by hand.

Surface Area to Volume Ratio: Granules have more surface area and thus, it reacts and dissolves faster, lumps with less surface area dissolve gradually, which is desirable in long-term use.

Flow Characteristics: Granular forms are ideal in automated conveying systems and dosing apparatus and reduce clogging and ease in controlling the process. Powder processing can be blocked or uneven because of lumps.

Handling Requirements: Granular materials prefer to be precise, think about fertilizer spreaders or dosing valves. The lumps are processed using heavy machinery and where uniformity is not so critical.

Agglomeration Risk: Granules can easily form agglomeration in wet conditions, but this problem can be prevented by appropriate packaging. Lumps are not so prone but difficult to dislodge when clumped.

| Feature | Granular | Lumps |

|---|---|---|

| Size & Shape | Small, uniform particles | Large, irregular chunks |

| Handling & Storage | Easy to transport, store, and measure | Bulkier, may require more storage space |

| Cost & Availability | Slightly higher cost due to processing | Often cost-effective for large-scale applications |

| Processing Speed | Fast and efficient | Slow, may require breaking |

| Industrial Versatility | Pharmaceuticals, plastics, food | Chemicals, mining, bulk industries |

Faster Dissolution & Reaction Rates: Small particle size promotes efficient chemical reactions and nutrient availability.

Better Mixing Capabilities: Uniform clays can be blended with ease which is vital in the production of fertilizer and manufacturing.

Easier Application in Agriculture: Granular form ensures reliable soil amendment and precision dosing.

Enhanced Precision: Consistent size supports accurate measurement, vital for pharmaceuticals and chemical processing.

Superior Flow Properties: Granules are easy to transport through conveyor systems and minimise the chances of equipment blockage.

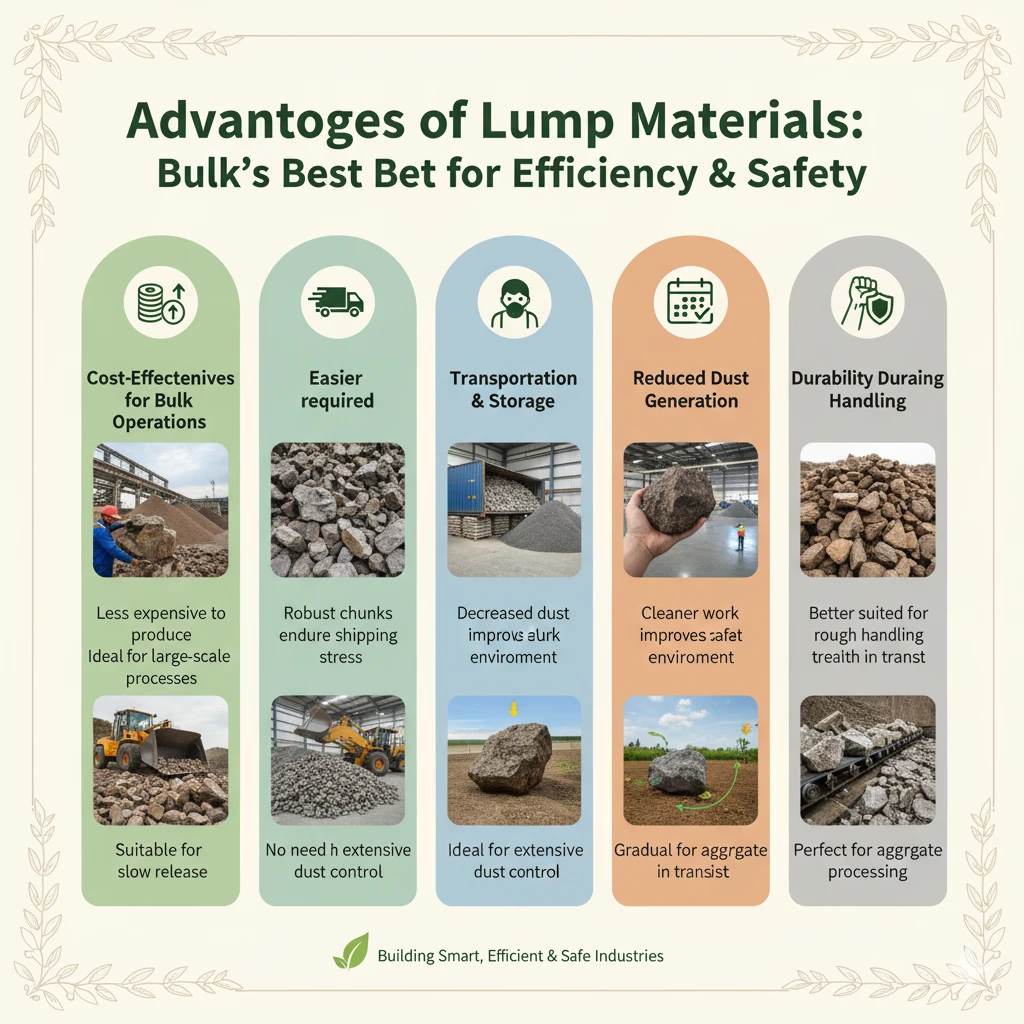

Cost-Effectiveness for Bulk Operations: Lumps are less expensive to produce and fit well in large-scale processes which require slow release.

Easier Transportation & Storage: Less packaging required; robust chunks endure shipping stress.

Reduced Dust Generation: Decreased dust diminishes safety in the workplace.

Long-Term Stability: Lumps have a slower dissolution rate, ideal for extended use or gradual soil amendment.

Durability During Handling: Better suited for rough handling in bulk storage or aggregate material processing.

During the production of sulfuric acid, granular sulfur is the favorite due to its easy dosing and purity. Bulk chemical processing and industrial manufacturing use lump sulfur, but it is less pure.

Fertilizers (e.g., sulfur, feldspar) in granular form are directly applied to soil, enhancing the absorption of nutrients and control of pH. Lump amendments are used to treat soil as time goes or as slow-acting nutrients.

Granular materials are employed as a homogenous composition in products such as plastics, rubber, glass, and ceramics by manufacturers. In certain processes, lumps can be used as aggregate fillers or slow-release agents, although in most cases, they need to be broken down further.

Special equipment is essential: granules will need dosing pumps, feeders of accurate size, closed areas to avoid agglomeration; lumps will need forklifts, bulk storage devices, and heavy equipment. To avoid the clumping or degradation of both forms, moisture management is very important. Control of temperature also helps to maintain the stability of the materials particularly in the sensitive chemical processing. Eliminate agglomeration in either form by means of a dry storage and climate controlled facilities.

The cost of granular materials is normally higher as they require refinement and granulation but are cheaper in terms of automation and reduced wastage. Lumps will be cheaper initially, but can increase the operational expenses through manual handling, dust control, and slower operation. Lump transportation is usually cheaper per ton, yet granular minimizes loss and does not compromise quality during the transportation process. The equipment investment is more inclined towards granular with regard to automation, although long-term expenditure could be equalized through waste levels and accuracy.

Is your process automated or manual?

Is it necessary to dissolve rapidly or release slowly?

To what extent is particle uniformity relevant?

Is transportation and storage cost a major issue?

Is low dust and enhanced safety required in your application?

Understanding the distinct properties of granular and lumps is essential for optimizing industrial operations. Granular materials empower precision, efficiency, and safety, while lumps excel in cost-effectiveness and bulk storage. Select the form that best aligns with your process needs, equipment, and end goals and consult suppliers for expert advice. Ready to make the right choice for your industrial application?

Granular materials are small, uniform particles ideal for automated systems; lumps are larger, irregular and suited for bulk, manual processes.

Lumps typically cost less for bulk operations, while granular materials provide savings through reduced waste and improved handling in automated settings.

Smaller particle size speeds up dissolution and mixing, boosts reaction rates, and increases process control; larger particles are slower to dissolve and handle.

Agriculture, chemical processing, pharmaceuticals, and manufacturing sectors all employ granular forms for efficient dosing and consistent results.

Lumps result from cooling molten material or mining, often due to aggregation or insufficient processing; management prevents unwanted agglomeration.

Control moisture, temperature, and packaging; use climate-controlled storage and proper equipment to minimize clumping and preserve flowability.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected]

|

Mr. RAJESH +91 99130 87000 |

|

Mr. JIGNESH +91 89800 70055 |