Industrial Coal Grades: Which is Best for Your Industry?

10 January, 2026

02 December, 2025

The modern paint and coating industry depends heavily on high-quality mineral fillers to achieve the right balance of performance, durability, and surface finish. Among these fillers, industrial clays play a crucial role in helping manufacturers create paints that are smooth, bright, stable, and long-lasting. Whether it’s decorative interior paint, industrial coatings, primers, or textured finishes, clays improve everything from viscosity control to opacity and cost efficiency.

In this detailed guide, we explore how Ball clay, Kaolin clay, Plastic clay, WBC clay, and White clay contribute to paint & coating production. Each clay type brings unique mineral characteristics that enhance the quality, consistency, and workability of coatings across different applications.

Industrial clays are naturally occurring minerals rich in aluminosilicates and fine particles. Their physical and chemical properties make them extremely valuable in paint production. Unlike synthetic additives, industrial clays offer a natural source of brightness, opacity, and viscosity control, allowing manufacturers to optimize their formulations efficiently.

These clays help create a stable paint matrix by supporting suspension, reducing settling, and improving overall coverage. They also allow paint producers to reduce the use of expensive pigments such as titanium dioxide without compromising visual quality. This makes industrial clays both performance-enhancing and cost-effective.

Industrial clays play multiple roles in improving paint characteristics:

Boost opacity & whiteness for brighter finishes

Improve viscosity & flow for smooth application

Increase strength and durability of the coating film

Enhance scrub & wear resistance

Provide better coverage while reducing pigment load

Support suspension to avoid settling during storage

Improve adhesion to surfaces in both water-based and solvent-based systems

Because of their multifunctional nature, industrial clays are used in everything from wall paints and putty to industrial coatings and protective paints.

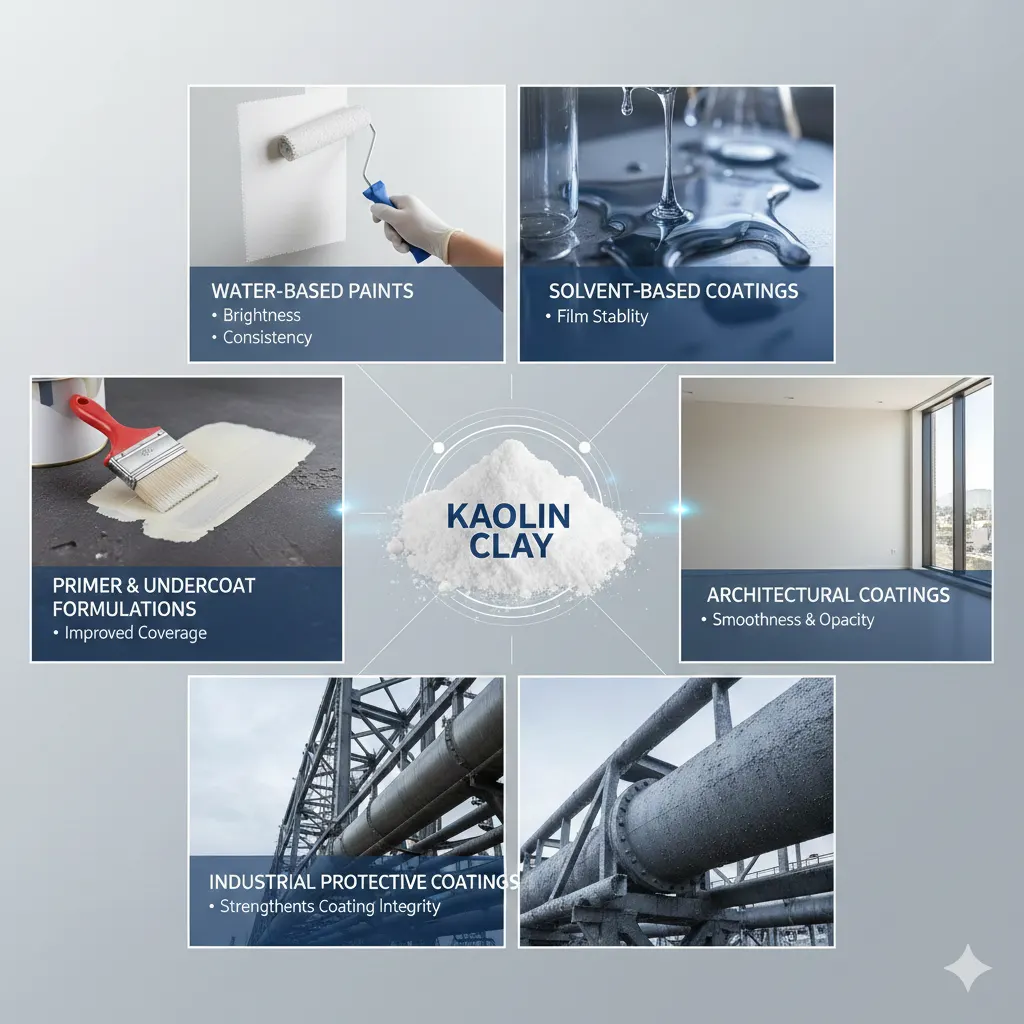

Kaolin clay is one of the most commonly used industrial clays in the paint industry, thanks to its exceptional whiteness, fine texture, and high brightness levels. It enhances opacity, improves surface smoothness, and provides better control over gloss levels. Kaolin clay powder also supports viscosity stability, enabling manufacturers to create coatings with consistent flow and finish.

Another benefit of Kaolin clay is its ability to partially replace higher-cost pigments, which helps paint manufacturers reduce production expenses without sacrificing film quality. Whether used in decorative coatings or industrial paints, Kaolin clay maintains performance under various application conditions.

Water-based paints: Provides brightness and consistency.

Solvent-based coatings: Enhances film stability.

Primer and undercoat formulations: Improves coverage.

Architectural coatings: Adds smoothness and opacity.

Industrial protective coatings: Strengthens coating integrity.

Ball clay is valued for its excellent plasticity, natural binding strength, and fine particle distribution. These properties allow it to enhance the structural stability of paints, making the coating film stronger and more durable. Ball clay uses include improving viscosity, preventing settling, and maintaining suspension during storage.

Ball clay powder also supports smooth application and helps achieve uniform texture, especially in thicker coatings. Its compatibility with other minerals makes it a reliable additive for both decorative and industrial paint formulations.

Undercoats & base coats: Adds thickness and adhesion.

Wall putty & fillers: Enhances binding strength.

Ceramic-effect paints: Improves texture.

Thick protective coatings: Increases durability.

Texture paints: Provides better control and depth.

Plastic clay is known for its elasticity, flexibility, and excellent leveling capabilities. It supports smooth flow and application, making paint easier to spread evenly across surfaces. Plastic clay improves adhesion, reduces cracking, and enhances the mechanical strength of coatings.

Because of its flexible nature, Plastic clay is widely used in textured, specialty, and water-based paints. It ensures better workability and helps create uniform coatings with superior finish quality.

Flexible coatings: Prevents cracking.

Textured wall paints: Adds flexibility and depth.

Specialty industrial coatings: Supports performance consistency.

Primers & putty blends: Enhances adhesion.

Water-based emulsions: Improves flow and leveling.

White clay is favored in premium decorative paints due to its high whiteness index and purity. It enhances brightness, opacity, and overall aesthetic appeal in interior and enamel-based paints. The fine particle size of white clay powder allows it to create a clean, smooth finish, making it ideal for high-end coatings.

Its reflective nature helps improve brightness while maintaining cost efficiency. White clay is also compatible with low-VOC and eco-friendly paint formulations, making it a popular choice for modern architectural coatings.

Decorative interior paints: Enhances whiteness.

Enamel coatings: Provides clean, glossy finishes.

Premium wall putty: Improves smoothness.

Eco-friendly coatings: Non-toxic and natural.

Distemper & matte finish paints: Enhances opacity.

WBC clay is used in heavy-duty and industrial-grade coatings due to its ability to enhance hardness, thickness, and weather resistance. It improves rheology, reduces cracking, and strengthens the film structure. Its mineral composition allows coatings to withstand environmental stress, chemical exposure, and temperature variations.

Because of these qualities, WBC clay is widely used in outdoor, marine, and industrial applications where long-term performance is essential.

Marine coatings: Enhances corrosion resistance.

Exterior wall paints: Improves strength.

Anti-corrosion paints: Adds durability.

Industrial protective layers: Supports long-term stability.

High-solid formulations: Strengthens thicker coatings.

Industrial clays are natural, eco-friendly, and non-toxic minerals that significantly reduce the environmental impact of paint production. They replace high-cost pigments, reduce energy consumption during manufacturing, and enhance the longevity of coatings. Their natural availability makes them a sustainable choice for manufacturers seeking cost-effective and efficient raw materials.

Using clays also supports better resource management, making them ideal for companies aiming to follow eco-conscious production processes.

| Clay Type | Opacity | Whiteness | Rheology Control | Durability | Common Uses |

|---|---|---|---|---|---|

| Kaolin Clay | High | Very High | Excellent | Medium | Primers, emulsion paints |

| Ball Clay | Medium | Medium | High | Very High | Putty, thick coatings |

| Plastic Clay | Medium | Medium | Very High | High | Textured paints |

| White Clay | Very High | Very High | Good | Medium | Premium decorative paints |

| WBC Clay | Medium | Low | Good | Very High | Industrial coatings |

Jay Ganesh Minerals is a trusted supplier of Ball clay, white kaolin clay, White clay, Plastic clay, and WBC clay for the paint and coating industry. Our clays are processed with precision to deliver consistent brightness, fineness, and performance. We maintain strict quality standards to ensure every batch meets industrial expectations, making us a preferred partner for paint manufacturers across India and global markets.

With reliable supply, expert grading, and customized solutions, Jay Ganesh Minerals supports manufacturers in creating high-performance and cost-effective coatings.

Explore Paint Production Insights

Industrial clays play a vital role in shaping the quality, performance, and durability of paints and coatings. Each clay whether Kaolin clay, Ball clay, Plastic clay, White clay, or WBC clay—offers unique benefits that enhance texture, brightness, adhesion, viscosity, and overall finish. By understanding their applications and properties, paint manufacturers can choose the right clay blend to improve their formulations.

For premium-quality industrial clays that meet the diverse needs of the paint and coating industry, Jay Ganesh Minerals remains a trusted and dependable source.

The most commonly used clays are Kaolin clay, Ball clay, Plastic clay, WBC clay, and White clay. Each type contributes different benefits such as opacity, viscosity control, durability, brightness, and smooth surface finishing.

Kaolin clay is used due to its fine particle size, high whiteness, and ability to enhance opacity. Kaolin clay powder improves film strength, offers a smooth finish, and helps reduce overall pigment cost while maintaining quality.

Yes. Ball clay is known for its binding strength and plasticity, which enhances film toughness, helps control viscosity, and prevents settling leading to longer-lasting coatings.

White clay is ideal for premium paints because of its excellent whiteness index, brightness, and reflective quality. It helps create clean, bright finishes and improves opacity without raising production costs.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected]

|

Mr. RAJESH +91 99130 87000 |

|

Mr. JIGNESH +91 89800 70055 |