Industrial Coal Grades: Which is Best for Your Industry?

10 January, 2026

08 November, 2025

The selection of a proper industrial mineral is one of the critical aspects that manufacturers of high-performance materials lose. Of these, the zircon sand and zirconium silicate are critical in the fields like ceramics as well as the glass production. Zircon sand is a natural mineral that is used naturally and exhibits a high level of thermal stability as well as durability whereas zirconium silicate is a processed version of the mineral used in relation to high-temperature applications and other specialized usage. The choice of material will influence the quality of the products, process effectiveness and cost-efficiency. This guide will discuss the characteristics, variations, industrial uses, and selection criteria of zircon sand and zirconium silicate hence enabling the industries to make the right decisions in regards to their production processes.

Zircon sand is a naturally occurring mineral chemically known as ZrSiO4 and it occurs in heavy mineral sand deposits located in various regions such as Australia, South Africa, and Mozambique. It is one of the most commonly mined industrial considerable minerals in the world, owing to its abundance in these areas.

High melting point (~2550°C)

Chemical stability in acidic and alkaline environments

Excellent thermal shock resistance

High density and opacity

Industries such as ceramics, foundries, and refractories use zircon sand to improve durability and thermal performance.

Zircon sand is physically of high melting point, heat resistance and chemical inertness that make it the ideal material to be used in high temperature industrial applications. The grains are usually small and are fine powders to rough sand and can be sorted by the use of sieving, washing.

The methods of production of zircon sand include mining, separation and refinements to exclude other impurities like titanium, iron and other silicates. Once processed, the sand may be utilized in such direct industries as glasses, ceramics, refractory materials, and foundry castings, where thermal stability and durability of the sand are highly important.

The natural characteristics of zircon sand include chemical composition, high melting point and low thermal expansion, which contributed to zircon sand usage in industries in the form of a basic material in many industries.

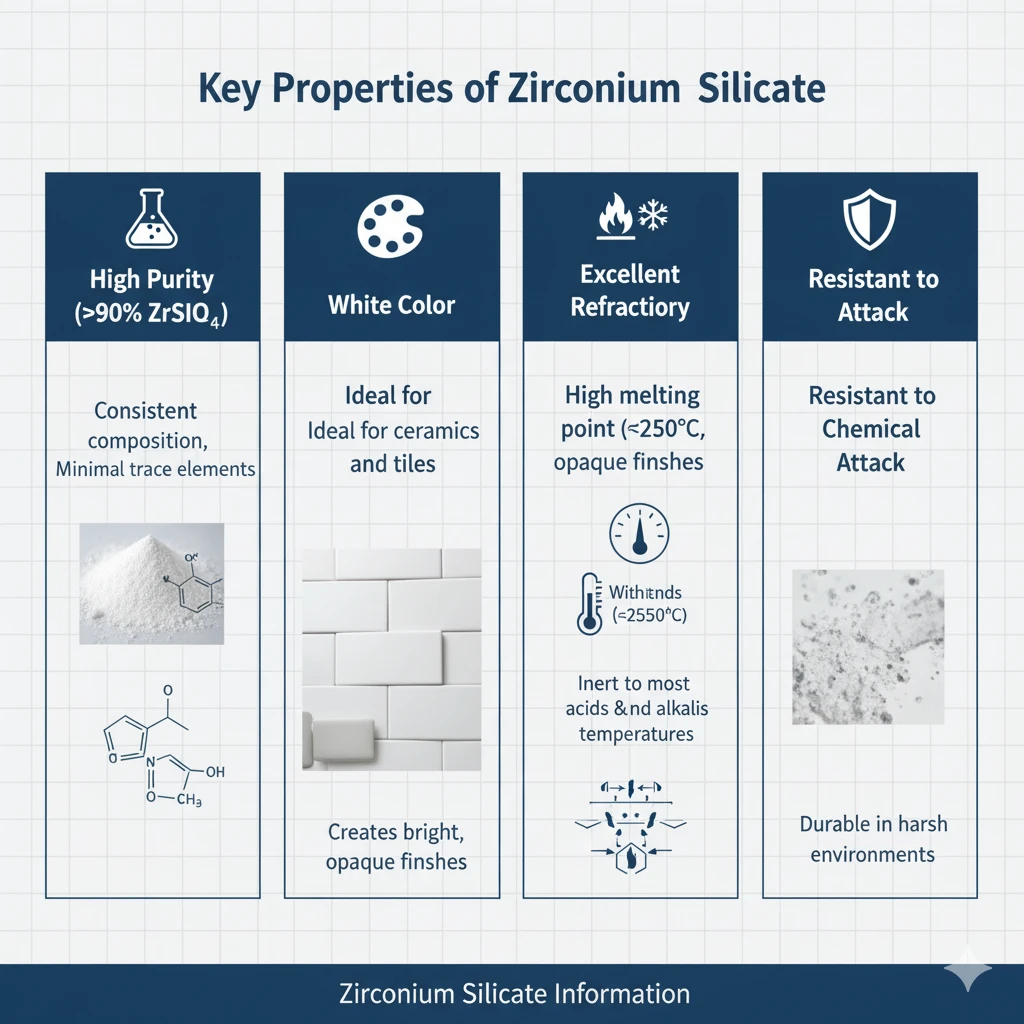

Zirconium silicate ZrSiO4 is a sort of processed derivative of zircon sand intended to be used in a particular industry. Zirconium silicate is highly purified, particle size controlled, and specific properties are produced to meet sophisticated ceramics, coating, and glazes as opposed to natural zircon.

High purity (>90% ZrSiO₄)

White color, making it ideal for ceramics and tiles

Excellent refractory properties

Resistant to chemical attack

It is produced by grinding zircon sand, eliminating impurities, and occasionally fusing in high temperatures so as to attain a uniform composition of the chemical. The outcome is a fine, even powder, which guarantees specific performance in strenuous tasks.

Zirconium silicate may be made of natural zircon sand or it may be fabricated under controlled conditions to meet certain industrial needs. It has purity levels that are usually up to 95 and particle size is fine tuned to performance requirements of ceramics, opacifiers and paint formulations.

Although it is closely similar to zircon sand, zirconium silicate is designed with high temperature and precision thus it cannot be neglected in industries that need uniformity, thermal stability and chemical resistance.

| Feature | Wooden Tiles | Engineered Wood Flooring |

|---|---|---|

| Composition | Ceramic or porcelain | Plywood base + hardwood veneer |

| Appearance | Mimics natural wood; wide design range | Real wood texture and finish |

| Durability | Highly scratch and moisture resistant | Susceptible to dents and water damage |

| Maintenance | Easy to clean, no refinishing needed | Requires polishing and care |

| Water Resistance | 100% waterproof (porcelain) | Limited, not ideal for wet zones |

| Installation | Simple tile-laying method | Needs professional installation |

| Cost | More affordable long-term | Higher upfront and maintenance cost |

| Applications | Indoors, outdoors, walls | Indoors, dry spaces only |

The key difference lies in purity. Zirconium silicate’s high purity makes it suitable for specialized applications, whereas zircon sand is more economical for general use.

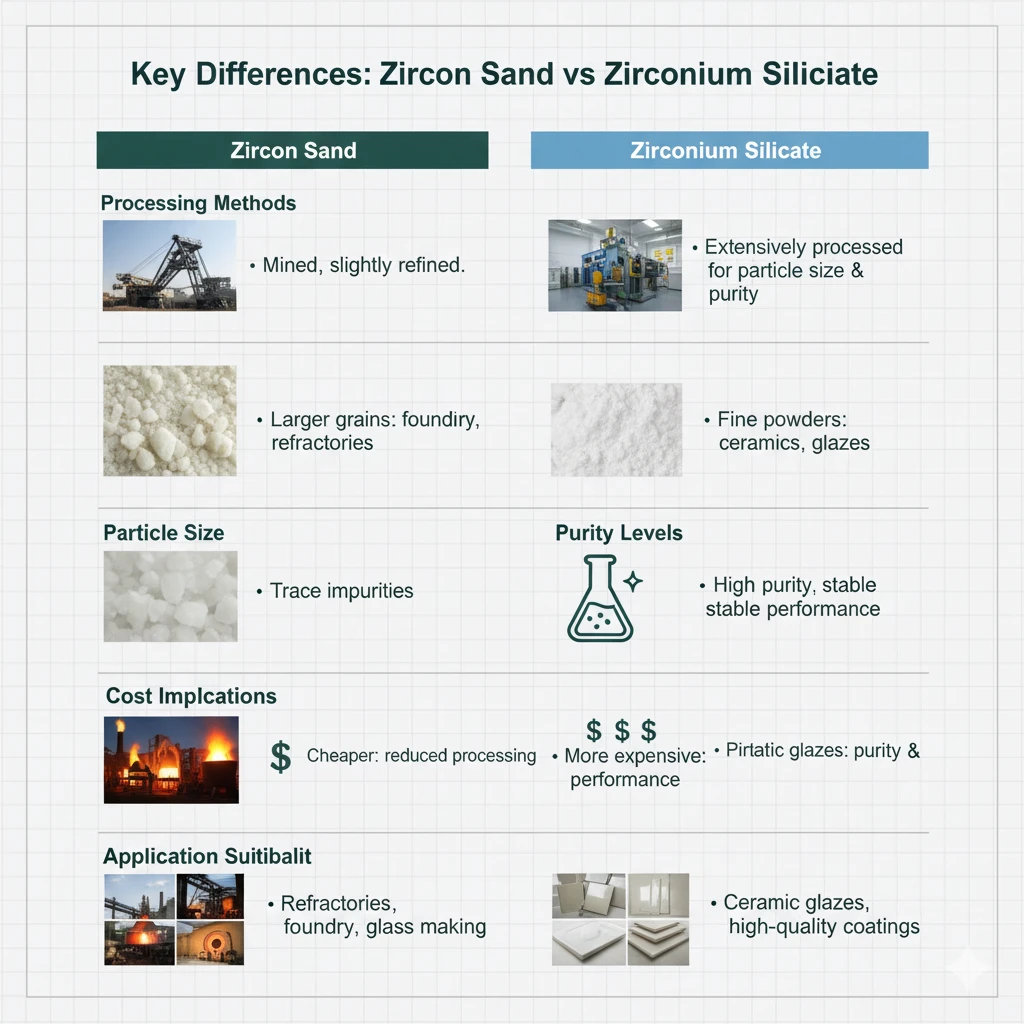

Though zircon sand and zirconium silicate share the same chemical formula, their processing, properties, and applications differ significantly:

Processing Methods:

Zircon sand is mined and slightly refined against impurities.

Zirconium silicate is extremely processed to get control of particle size and high purity.

Particle Size:

Zircon sand: Larger grains that can be used in bulk use, such as foundry casting and refractories.

Zirconium silicate: Fine powders to deal with ceramics, glazes, and coating.

Purity Levels:

Zircon sand: It has impurities of trace elements, which can interfere with the high-precision processes.

Zirconium silicate: Premium grade will guarantee a stable performance in delicate uses.

Cost Implications:

Zircon sand is normally cheaper because of the reduced processing demands.

Zirconium silicate is more expensive because of processing, purity and performance advantages.

Application Suitability:

Zircon sand: It can be used in refractory materials, foundry casting, glass making and other high temperature purposes.

Zirconium silicate: It is used in ceramic glazes, opacifiers, high quality ceramics, and high quality coatings.

Knowing such differences is critical in choosing the material because the incorrect form of a material may cause inefficiencies, poor quality of the product, and high costs.

Understanding these differences is essential for material selection, as using the wrong form can lead to inefficiencies, reduced product quality, and increased costs.

Zircon sand is a highly versatile mineral and it can be used in various industries:

Casting and Foundry: Can be used as a lining in molds and refractories because it is very resistant to high temperature.

Refractory Materials: The materials are necessary to make bricks, mortars and linings of the kiln to withstand high temperatures.

Glass Manufacturing: Enhances thermal and chemical stability in glass which minimize expansion and cracking.

Nuclear Industry: It is low in neutron absorption which is the reason why it is used in nuclear reactors and special shielding material.

Zircon sand is an inexpensive bulk, high-temperature industrial material with its natural availability, thermal stability and chemical resistance.

Zirconium silicate is used in the need of accuracy, purity and performance:

Ceramics and Glazes: Thermal stability, whiteness, and smooth finishes of high quality ceramic products.

Opacifiers: Plays a major role in paints and coating to enhance the durability as well as the color.

High Tech Ceramics: Electronic, dental, and structural applications are the use of ceramics of this type, based on chemical inertness and ability to withstand heat.

Paint and Coatings: Improves the resistance to weather and thermal stability in industrial finishes.

Its finely controlled particle size and purity ensure consistent performance, making it indispensable for high-value industrial applications.

Selecting the right material depends on several factors:

Applications: zircon may be used as bulk, high-temperature, and refractory material, zirconium silicate to make precision ceramics, coating, and glazes.

Budget Factors: Zircon sand is cheaper to use in large-scale industries, but zirconium silicate, though it is more expensive, would offer high performance in the specialized industries.

Performance Requirement: Take into account the particle size, purity and chemical composition depending on the final use.

Industry Standards: It is important that the industry regulations are followed in terms of heat resistance, thermal stability, and chemical inertness.

Assessing these factors ensures optimized product performance, efficiency, and cost management.

Zircon-based materials offer several industrial advantages:

Thermal Stability: Retains integrity when subjected to a high temperature.

Chemical Resistance: Resists corrosive and reactive chemicals.

Durability Benefits: Refractory, Ceramic and glass Intensive service with long service life.

Cost-Effectiveness: Compares performance to operational efficiency and is mostly used in bulk industry.

These advantages render zircon sand and zirconium silicate a very important ingredient in foundry casting, ceramic glazes, and high temperature industry.

Get Expert Industrial Insights

Understanding the differences between zircon sand and zirconium silicate is essential for selecting the right industrial mineral. Zircon sand is ideal for bulk, high-temperature, and refractory applications, offering cost-effective thermal and chemical stability. Zirconium silicate, with its fine particle size and high purity, is perfect for ceramics, coatings, and opacifiers where precision and performance matter.

Industries must weigh cost, performance, and application requirements when choosing between these materials. By selecting the appropriate form, manufacturers can enhance efficiency, product quality, and durability. Future advancements in zircon-based materials promise continued growth across industrial sectors, ensuring long-term benefits for manufacturers.

That’s where Jay Ganesh Minerals steps in. With over 20 years of industry experience and operations across multiple mines, we are committed to delivering premium zirconium silicate and mineral products worldwide. Jay Ganesh Minerals Whether your needs center on ceramics, refractories, or cutting-edge industrial uses, Jay Ganesh provides tailored solutions end-to-end from mining and processing to global export.

A: Zircon sand (ZrSiO4) is a natural mineral used in high-temperature and refractory applications.

A: Zirconium silicate is a processed form of zircon sand with higher purity and controlled particle size, used in ceramics, coatings, and opacifiers.

A: Consider application type, budget, purity requirements, particle size, and industry standards.

A: Zircon-based materials provide thermal stability, chemical resistance, durability, and cost-effective performance in industrial applications.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected]

|

Mr. RAJESH +91 99130 87000 |

|

Mr. JIGNESH +91 89800 70055 |