Zirconium Silicate vs Zircon Sand: Industry Guide

08 November, 2025

09 October, 2025

Coal is still among the most popular power sources used worldwide, in cement production, and in heavy industry. The calorific value of coal is one of the first questions that one should ask when buying coal. This value informs you of the amount of energy that will be emitted by the coal. Knowing your product prior to making a purchase can avoid expensive surprises, ensure consistent performance and save your bottom line.

The coal calorific value is the quantity of heat produced when a given quantity of coal is burnt under controlled conditions. That is, it demonstrates the energy value of coal per kilogram. The greater the calorific value, the greater the amount of energy you get out of an equivalent weight of coal and this tends to incur less cost per unit of heat.

Calorific value is either measured in kilocalories per kilogram (kcal/kg) or kilojoules per kilogram (kJ/kg). The buyer is always to ensure that the unit and basis quoted are correct. As an example, a figure of a coal calorific value kJ /kg may be higher because kilojoules are bigger units than kilocalories, but the energy content remains identical on conversion.

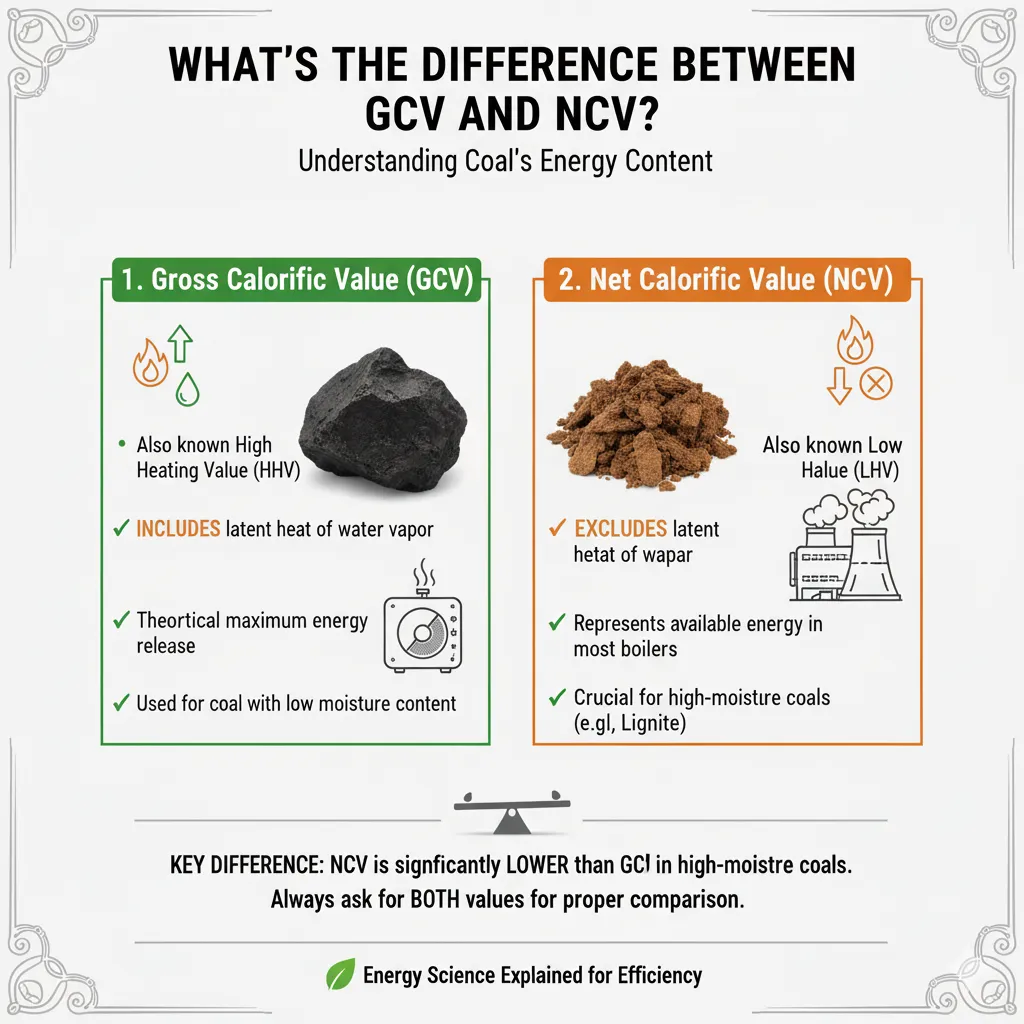

In supplier documentation, you will frequently come across the concept of coal GCV (Gross Calorific Value) and NCV (Net Calorific Value). The latent heat of water condensing is also included in GCV, also known as the high heating value. The latent heat is subtracted, giving NCV or low heating value, and the amount of available energy in most actual boilers.

The variations in moisture and hydrogen content of coals result in the fact that NCV may be much lower than GCV, particularly in high moisture coals such as lignite coal or brown coal lignite. It is important to always enquire as to the value they are quoting and to demand both numbers where necessary as a way of proper comparison.

The cost of coal heat value that you buy directly influences your cost of energy. High ash, low-energy coal In a boiler that was designed with high calorific coal, the use of high ash coal may result in incomplete combustion, high emissions, and high wear. Alternatively, the purchase of coal of higher calorific value than necessary might prove expensive per tonne but economical on transportation and handling since less is necessary to generate the same amount of heat.

Even a minor variation in calorific value in such industries as power generation, cement kilns, or steelmaking can lead to significant cost variations throughout the duration of a contract.

Coal types vary widely in energy content:

Lignite coal / brown coal lignite: Very high moisture and low energy content, often between 2,500–3,500 kcal/kg (≈10–14 MJ/kg). This low lignite coal calorific value means more fuel is needed for the same energy.

Sub-bituminous and bituminous thermal coal: Moderate moisture and higher energy content, commonly 4,000–6,000 kcal/kg.

High calorific value coal: Premium grades with over 6,000 kcal/kg, used in specialized industrial or export markets.

Indonesia coal: Known for a wide range of export grades from about 4,200 kcal/kg up to 6,200 kcal/kg (as received). Buyers should check the moisture basis because Indonesia coal calorific value is often quoted on ADB (air-dried) or GAR (gross as received) basis.

Known for a wide range of export grades from about 4,200 kcal/kg up to 6,200 kcal/kg (as received). Buyers are to pay attention to the moisture basis as Indonesian coal calorific value is usually quoted on an ADB (air-dried) basis or a GAR (gross as received) basis.

Understanding these ranges helps you quickly spot whether a quoted number matches the type of coal offered.

To use a real-life example, we should refer to Jay Ganesh Minerals, which is a long-standing manufacturer and distributor located in Morbi, Gujarat, India. They specialize in both industrial clay products and supplying different coal types such as Indonesia coal and lignite coal.

Jay Ganesh Minerals produces a wide array of high-quality clay minerals including:

Ball Clay

Kaolin Clay (also known as China Clay)

Plastic Clay

WBC Clay (white burning clay)

Semi-Plastic Clay

White Clay

Very Fine Processed Clay

Zirconium Silicate

They are applied in industries like ceramics, paper, paint, construction, cosmetics and so on. Their clay products are treated in a manner that they are uniform in terms of purity, the size of particles, and the level of impurities.

On the coal side, Jay Ganesh Minerals sources and supplies:

Indonesia Coal, known for relatively high energy content and lower ash levels, which makes it popular in applications demanding higher calorific performance.

Lignite Coal, which is lower in carbon content and higher in moisture, but cost-effective for certain uses.

They operate several mines, ensure sustainable supply, and emphasize various quality checks for coal fuel, including monitoring ash, moisture, sulfur, and other important parameters.

A bomb calorimeter test, which is a routine of an accredited laboratory, is the best method of measuring the calorific value under ASTM or ISO standards. In this test, the sample of coal is weighed in a sealed chamber (bomb), which is enclosed with water. The increase in temperature in the water indicates the amount of heat emitted by the coal and it is reported as GCV.

An adequate test must be well prepared in terms of sample preparation, weighing, and calibration. That is why the majority of large buyers insist on having a separate lab certificate for each shipment. This is the ultimate test and must constitute your sale agreement.

When you receive a specification sheet or lab certificate, look for:

Coal GCV in kcal/kg or kJ/kg, with the moisture basis stated (ARB, ADB, dry basis).

Proximate analysis: Moisture, ash, volatile matter, and fixed carbon.

Ultimate analysis: Carbon, hydrogen, nitrogen, sulfur, and oxygen percentages.

Ash fusion temperatures, sulfur content, and other parameters relevant to your application.

Having these numbers helps you calculate not just the calorific value but also the expected performance of the coal in your process.

In some cases, you can have the idea that you will require a brief screening procedure prior to placing a comprehensive analysis. Two common approaches are:

Dulong Formula: An equation that is commonly used to estimate the calorific value based on ultimate analysis (C, H, O, S). This is convenient, though not very precise, with high-moisture coals such as lignite and brown coal.

Proximate-based prediction models: These involve moisture, ash, and volatile matter in order to predict GCV. Other portable analyzers also purport to provide instant readings, though they have variable accuracy.

The two are most suitable in initial screening as opposed to ultimate pricing. A bomb calorimeter test is needed in case of important purchases.

While no field test replaces a lab analysis, a few on-site checks can flag potential problems:

Visual inspection: Darker, shinier coal often indicates higher rank, but appearances can be misleading.

Moisture meters: Quick check of surface moisture, though total moisture may still be higher.

Sample splitting: Taking multiple increments from different parts of a stockpile or shipment helps produce a representative sample for later testing.

These quick checks help you decide which samples to send for laboratory analysis.

Comparing the numbers reported on different bases is one of the most frequent errors. A coal could be 5,500 kcal/kg ADB and 5,000 kcal/kg ARB due to moisture content. It is always better to convert values to identical units (kcal/kg or kJ/kg) and basis (ARB, ADB, dry).

Remember: 1 kcal = 4.184 kJ. A number of 23,000 kJ/kg approximates 5,500 kcal/kg. Units and bases are needed to make comparisons of like with like and prevent concealed surprises.

For large or repeated shipments, add clear clauses to your purchase contract:

Sampling and testing procedures must follow agreed standards.

An independent lab chosen by both parties measures the coal calorific value of a composite sample.

If the result is below an agreed tolerance, the price adjusts or the shipment can be rejected.

Retain sealed reference samples to resolve disputes.

These steps provide transparency and reduce risk for both buyer and seller.

GCV includes the latent heat from water vapor, NCV does not. NCV is typically lower, especially in moist coals.

It gives a rough idea but can be significantly off due to high moisture and volatile content. Always confirm with a bomb calorimeter test for lignite coal calorific value.

Higher moisture and ash reduce usable energy and may increase handling costs.

Multiply by 4.184 (or divide by 4.184 to go from kJ/kg to kcal/kg).

Request an independent laboratory bomb calorimeter test for every batch.

Verify GCV/NCV, moisture, ash, and other critical parameters on the same basis.

Convert all calorific values to a common unit for fair comparison.

Include clear sampling and acceptance clauses in the contract.

For unfamiliar suppliers or grades like Indonesia coal, test initial samples before committing to large volumes.

The coal calorific value is not a mere technicality when it comes to the purchase of coal; it is a necessity to check the coal calorific value to control costs, maintain a steady flow of energy and to meet the environmental standards. Knowing how to measure the calorific value, interpretation of numbers and verification of numbers helps you to negotiate better, prevent disputes, and select the appropriate grade to suit your requirements. To ensure the safety of your business, always use consistent laboratory tests along with proper handling of samples as well as being very specific on the terms of contract.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected]

|

Mr. RAJESH +91 99130 87000 |

|

Mr. JIGNESH +91 89800 70055 |