Types of Clay Used in Ceramic Industry

03 March, 2026

02 October, 2025

There is a chance that you have heard the words coking coal and non-coking coal bandied around and particularly in industries such as coal and steel production or power generation. Nevertheless, what is really so different about them? It is not only a small detail, but it actually determines where these coals are going to be used. Remember it, as in the varieties of wood for various work, you could not make a strong table out of balsa, would you? You see, it is sort of the same with coal. We will have to deconstruct the specialty of coking coal (or metallurgical coal or met coal) and how non-coking coal remains a large part.

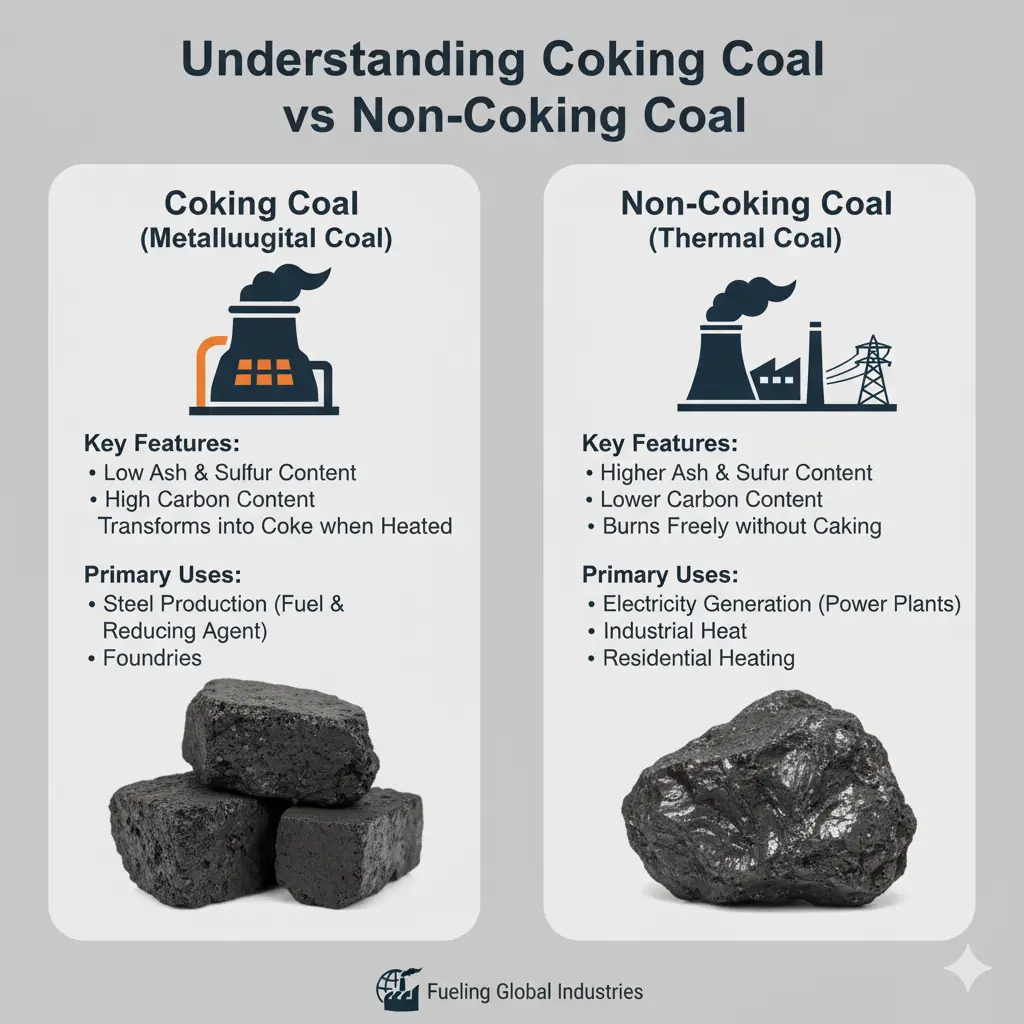

Coking coal uses are primarily in making coke, which is an important component in the production of steel whereas the non-coking coal forms the prime source of electricity generation.

The key distinction is that their capacity to become soft, bulky and hardened into a solid mass (coke) in the event of heating, without air; coking coal is very good with that, non-coking is not.

The coking coal production usually contains more carbon and specific volatile matters and the non-coking coal usually contains more ash and moisture.

Even though blast furnaces cannot operate without coking coal during the steelmaking process, power plants greatly rely on non-coking coal.

So, what is so special about coking coal and non coking coal? It is actually just a matter of what you want to do with it. Imagine coal with a complete spectrum of properties, and the position in that spectrum determines the primary occupation of coal.

The special type used especially to produce coke is coking coal, commonly referred to as metallurgical coal or met coal. Coke refers to that hard, porous material you require in making steel, particularly in blast furnaces. When coking coal is heated in the absence of air, it becomes soft, swells and again hardens to coke. It is characterized by the ability to create a strong, workable mass.

It also has higher carbon and lower moisture and ash levels than non-coking coal. The quality of the coke is greatly affected by the nature of the coking coal, and there are various grades of coke such as hard coking coal, medium coking coal and semi-soft coking coal, each of which can be used in blending the coking industry.

Coking coal has specific properties that make it suitable for coal and steel production:

High Carbon Content: This is essential for forming coke, which provides both heat and carbon in steel-making.

Low Volatile Matter: Coking coal should have low gases and impurities, so the coke is strong

Hard and Brittle: It can withstand high pressure in blast furnaces without crumbling.

Good Caking Ability: When heated, it melts slightly and forms solid lumps (coke).

However, non-coking coal does not undergo the same magic on heating. Although it may leave some good residue, it will not create the good, strong, coherent coke required in the blast furnaces. Rather, it is the power generator, and its primary task is to burn and provide steam to operate turbines.

It will always be found to have a greater amount of volatile matter, and more ash can be tolerated by it. Although not so good at producing coke, some varieties of non-coking coal still find applications in other industries, such as some direct-reduction iron processes, or in the production of other products such as cement.

Non-coking coal is designed for energy production, not steel. Its properties include:

High Volatile Matter: This helps it burn easily and produce heat.

Lower Carbon Content: It is not suitable for making coke.

Softer Texture: It breaks easily and burns completely when heated.

Higher Moisture: Some non-coking coal may contain water, which slightly reduces its heating value.

What exactly then makes coking coal different from non-coking coal? It all revolves around the behavior of the coal when heated, particularly in the absence of air. Consider it as baking - ingredients and temperature are a concern.

Carbon is coal, but it is the quantity and the way it is organized that make the difference. Coking coals tend to be more carbon rich with the majority falling within the medium-volatile bituminous range. This implies that they are more adult, so to speak. Non-coking coals, however, are free to possess a broader variety of carbon content, typically incorporating down the ranks such as the sub-bituminous or lignite.

Volatile matter is that which is expelled as gas on heating coal. The volatile matter has a sweet spot of coking coals, which is usually in the range of 20-35%. And too little it will not soften, and too much may become messy. The gunk that remains is non-combustible, Ash. With coking coal, it tends to be a preferable practice that the coal has less ash because this implies more usable carbon in the process. The coals which are not usually coked, particularly those utilized in the generation of power energy, are often able to withstand greater amounts of ash.

Here is where magic (or disaster) occurs. Heated coal is caking and this is softened, gooey and solidified back into a solid mass. It is this creamy plastic stage that makes it swell and take the porous form required in coke. It is this power to become a solid, powerful lump that is essential in the process of steelmaking. This is not actually done by non-coking coals or free-burning coals. They may disintegrate or simply evolve into ashes without creating the plastic intermediary. This disparity is commonly quantified by examinations such as the Free Swelling Index or the Roga Index.

Here’s a quick look at typical ranges:

| Property | Coking Coal (Typical) | Non-Coking Coal (Typical) |

|---|---|---|

| Carbon Content | 80–90% | 70–85% |

| Volatile Matter | 20–35% | 30–45% |

| Ash Content | < 10% | 10–25% |

| Caking Ability | High | Low to None |

Consider it in the following way: coking coal is a good bread dough, it becomes soft, rises, and supports its structure. Non-coking coal is rather sand; when it is heated, it remains sand, or perhaps it becomes dust.

So, where does all this coal end up being used? It really boils down to what kind of coal you're talking about. Coking coal and non-coking coal have pretty distinct jobs in the industrial world.

This is the largest of coking coal applications. It is the foundation of steel production by the old method of the blast furnace. The heating of coking coal in the absence of air produces coke. This coke is not only fuel, but it is a chemical agent. It performs two important functions in the blast furnace:

Provides Heat: It burns, creating the super high temperatures needed to melt iron ore.

Acts as a Reducing Agent: It strips oxygen away from the iron ore, turning it back into metallic iron.

Offers Structural Support: The coke forms a porous but strong structure that holds up the weight of the iron ore and other materials in the furnace.

The entire process of the blast furnace to make iron and then steel could not be done without coke. The efficiency and quality of the steel produced are directly related to the quality of the coke, which in turn is directly related to the quality of the used coking coal. Consider it as baking a cake, you must have the appropriate ingredients in the right amounts.

Non-coking coal, often called thermal coal, has a different fate. Its principal one is electricity generation. In a power plant, when you burn thermal coal, the heat generated boils water and produces steam. This steam further rotates turbines and ultimately, the turbines rotate to generate electricity. It is a fairly simple exercise, although it takes a lot of coal.

Electricity Generation: This is the primary use, powering homes and industries.

Industrial Heat: Some factories use it directly for process heat.

Cement Production: It's also used in cement kilns.

Unlike coking coal, thermal coal doesn't need to form that strong, porous structure. Its value is in its energy content, measured by its calorific value.

While steelmaking and power generation are the main players, both types of coal find their way into other areas:

Coking Coal: Can be used in smaller amounts for things like producing calcium carbide, silicon metal, and in some sintering processes for iron ore.

Non-Coking Coal: Beyond power plants, it can be used in industrial boilers, for producing synthetic gas (syngas), and in some manufacturing processes where heat is the main requirement. Some lower-grade non-coking coals might even be used in smaller blast furnaces or for specific smelting operations where the coke quality isn't as critical.

There you have coal, then is it the proper coal to make coke with? Coal is not coal when it comes to this particular job. It is similar to baking a cake; you have to use the correct ingredients in the correct quantities, or you will find yourself having a brick, not a treat.

Why is coal a good coke raw material? Well, it's a mix of things. You want coal, which, when heated without the presence of air, becomes soft and swelled, and fuses into a solid, porous substance. This is known as carbonization and the process requires certain conditions.

Coking coals are usually good with a relatively low ash content of 1 to10 %. They must, too, have some quantity of volatile matter, usually in the 18 to 45 % range, assisting in that important softening and swelling. An excellent indicator is also the reflectance of the vitrinite, which is a constituent of coal, and typically lies between 0.6 and 1.8 % in appropriate coking coals.

Single supercoal is hard to come by, which is why it is quite uncommon to encounter a single type of coal that is solely suitable to produce coke. In the majority of cases, coke manufacturers employ a mixture of various coking coals. This amalgamation is a science and an art. It aims to blend coals of different characteristics, such as different amounts of volatile matter, ash and swelling characteristics, to come up with a final product that is of the greatest strength and stability.

The whole thing is in the fine-tuning of the formula so that the coking plant will run efficiently and the coke that is produced will be up to the rough demands of the steel industry. The correct proportion of this blend is what is important in the production of a coke that is more thermally resistant than others.

But what about non-coking coal? These coals simply do not, as the name implies, have what it takes to become good metallurgical coke. Heated, they may leave residue, but that will not be the coherent, strong material that is required in steelmaking. They are frequently richer in ash and do not have the required softening and swelling characteristics during heating.

Although certain coals do not require coking, such as in other steelmaking processes, such as direct-reduced iron production, they do not typically fit in the blast furnace, where the particular properties of coke are literally crucial. Attempts to apply them to traditional cokemaking are normally a disaster waiting to happen.

In discussing the origin of coking coal, there are a few places that can be mentioned. Australia is a giant; essentially, it controls the international export market. Then there are the other countries with high reserves and production, such as Canada, the United States, South Africa, Russia, and China.

It is interesting in that these countries are generating a lot, but much of it is kept in the home country, particularly in China, to feed their huge steel sectors. The volumes traded all over the world, although significant, do constitute only a small portion of total production.

We have therefore noticed that coking and non-coking coals are two quite different things, primarily due to their intended purpose. To produce coke, coking coal is the star in the process, which is very significant to the steel industry. It has certain properties that enable it to soften, swell and thereafter create that coke structure that is very strong.

Non-coking coal is, however, a power plant workhorse as it produces power by making steam to produce electricity. Although there exists a degree of overlap and some of the coals may be applied in either case, depending on the circumstance, their fundamental jobs are different. These differences make us grateful for the fact that these various forms of coal are part of our industrial world.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected]

|

Mr. RAJESH +91 99130 87000 |

|

Mr. JIGNESH +91 89800 70055 |