Zirconium Silicate vs Zircon Sand: Industry Guide

08 November, 2025

03 October, 2025

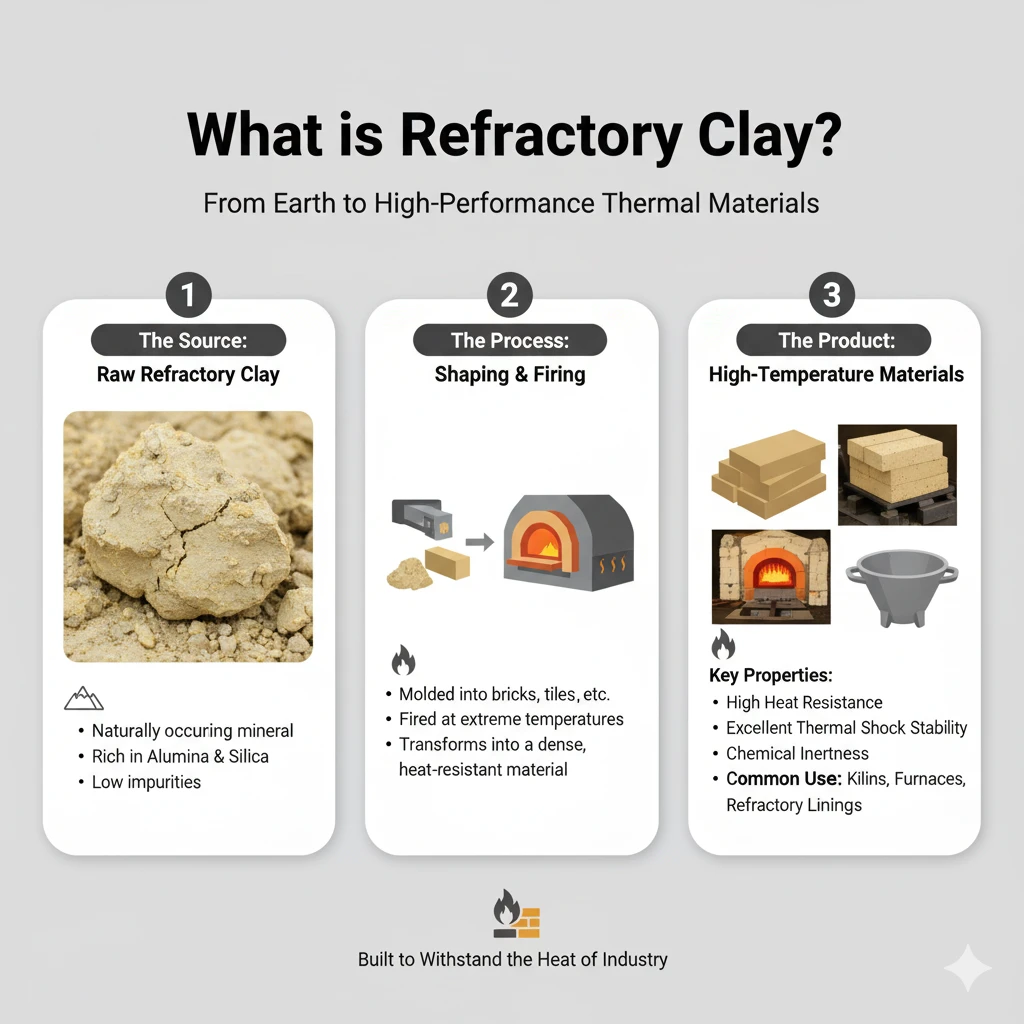

Fire clay (also known as refractory clay) is a specialty clay material that has been designed to withstand very high temperatures, wear, and abrasion, and chemical aggressors. In furnaces, kilns and most heavy-industry processes, it is essential that normal materials would otherwise break down. It may be to construct a cement plant, a pizza oven, or lining a steel furnace: the knowledge of refractory clay and clay fire bricks can make sure that it is safe, efficient, and it will last.

Refractory Clay: This type of clay is an alumino-silicate type of clay that can withstand extremely high temperatures without melting, becoming deformed, or even chemically impaired. The two important elements are alumina (Al₂O₃) and silica (SiO₂), which may have kaolinite, mullite as well as other minerals which may be included.

Refractory clay is also commonly referred to as fire clay, which can be used interchangeably with fire clay, but sometimes the narrower definition is included as types that contain specific ratios of alumina and silica. Refractory clay, compared to plain clay, has the following properties: the purity of the mineral, that it can withstand fluxing (due to the presence of impurities such as alkalis or limestone), and that it is capable of melting at a high temperature.

The materials are utilized extensively in fire clay refractories such as refractory clay bricks, clay fire bricks and fire clay cement, among others. Their composition should be regulated such that the material can resist repeated thermal cycling, high mechanical loads and aggressive slag/gases.

To perform well, refractory clay must exhibit several critical properties:

Refractoriness / Fusion Temperature (PCE): Frequently characterized as the pyrometric cone equivalent (PCE) or the fusion point. Fire clay bricks (a common form of refractory clay bricks) have the ability to withstand high temperatures (in the range of ~1,500-1,800 °C before they start to melt. Even further is pushed by higher-alumina grades.

Thermal Conductivity & Insulation: Refractories that are dense are better conductors of heat and this is handy in load-bearing, unless you want to have a lot of heat transferred at the same time. This is because more porous or insulating fire clay refractories can save energy by reducing the amount of heat lost, but insulation should be engineered in such a way that it does not undermine the strength of the refractories.

Mechanical Strength: It must have compressive strength and be able to bear loads under heat conditions and this is vital, particularly in heavy applications such as steel furnaces and cement/rotary kilns. The monolithic refractories and bricks should also be resistant to abrasion and spalling.

Thermal Shock Resistance: The capacity to be resistant to high-speed changes in temperature without breaking. Refractory clay should have the capability to withstand heating and cooling since a minor crack can cause service failure.

Chemical Resistance: Slags, alkalis, acids, or fluxes attack refractory materials depending on the process. Fire clay refractories are typically acidic (high in silica/alumina) and, as such, resistant to acidic slags but less efficient in strongly basic environments (except specially made).

Several types exist; the right choice depends on service temperature, mechanical demand, exposure to slag/chemicals, and insulation needs.

| Type | Typical Alumina / Silica Composition* | Main Features | Best Use Cases |

|---|---|---|---|

| Standard Fire Clay | ~25–45% Al₂O₃, remainder mostly SiO₂ + impurities | Moderate refractoriness, good toughness, relatively economical | General furnace linings, stoves, low to medium temperature bricks |

| Low-Porosity Fire Clay Bricks | Similar base composition but denser, fewer voids | Higher strength, better slag resistance, less permeable | Areas exposed to slag, lining where wear is high |

| High-Alumina Bricks | >45% Al₂O₃, sometimes 50–70% or more | Higher refractoriness, greater load bearing at high temp | Steel furnaces, cement kilns, incinerator throat zones |

| Insulating Fire Bricks (IFB) | Lower density, higher porosity; composition may trade off some alumina | Good insulation, light weight, lower conductivity | Backup lining, insulation layers behind load-bearing bricks |

| Silica Bricks / Basic / Neutral Refractories | Silica bricks have very high SiO₂; basic refractories (lime or magnesia) differ; neutral refractories have balanced chemistry | Each has tradeoffs in resistance to acid/basic slags; silica bricks resist acidic environments well | Silica bricks for glass furnaces; basic refractories in basic slag environments |

Composition percentages vary by manufacturer and standard (ASTM, ISO etc.).

ASTM standards categorize refractory clay bricks and high-alumina bricks in chemical group, physical characteristics (porosity, density) and test behavior. The decision between acidic or neutral or basic refractories is determined to a great extent by the presence of acidic or basic slags in the environment.

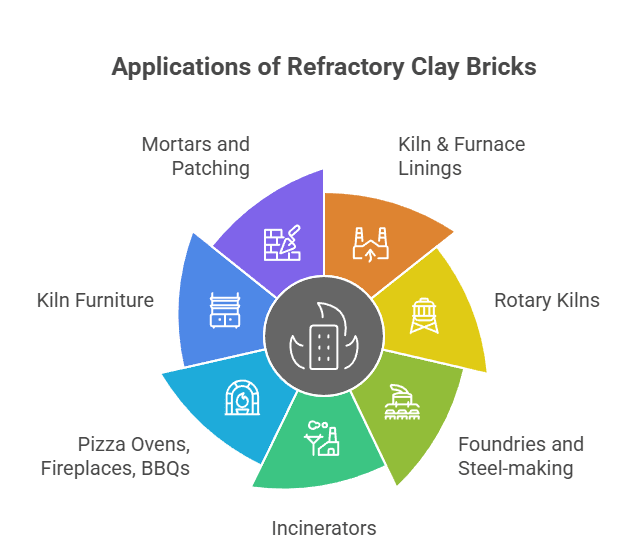

Refractory clay bricks and related fire clay refractories are used wherever high temperature, corrosion, or mechanical abrasion are at play. Key applications include:

Kiln & furnace linings: Ceramics, brick manufacturing, glass melting. Bricks must remain stable under constant high heat cycles.

Rotary kilns: In cement and lime manufacture, where interior linings face heat, abrasion, and chemical attack from combusted materials and slag.

Foundries and steel-making: Working faces in furnaces, ladles, pouring zones places that see molten metal or slag contact.

Incinerators: Where waste is burned, sometimes producing corrosive gases. Fire clay refractories protect the structure and ensure thermal containment.

Pizza ovens, fireplaces, BBQs: Even small-scale or domestic appliances benefit from fire clay bricks because they retain heat well and resist thermal cycling.

Kiln furniture: Posts, shelves, setters in ceramic kilns made of refractory clay bricks so they don’t warp or crack at high temperature.

Mortars and patching: Used for laying refractory clay bricks and patching. Fire clay cement often has similar overall composition to the bricks so that joints don’t become weak points

It might seem tempting to use regular clay if you’re in a pinch, but there are major risks:

| Aspect | Regular Clay | Refractory Clay |

|---|---|---|

| Fusion / Melting Point | Low; deforms or melts at relatively modest temps (~1,000–1,200 °C or even less depending on impurities) | Very high (often 1,500–1,800 °C and above) |

| Chemical Purity / Impurities | Higher amounts of alkalis, lime, iron, etc., which lower heat stability and promote slag interactions | Controlled impurities; minimized fluxing agents; matched to environment |

| Mechanical Strength under Heat | Poor; tends to spall or crack when heated and cooled repeatedly | Designed to resist thermal shock, creep, abrasion |

| Duration / Stability | Much shorter; failure likely under demanding conditions | Longer life, better stability under repeated cycles |

Therefore, the following is the answer to the question “Can I use regular clay instead of refractory clay?”: No, usually, unless the heat is low and there are few cycles and the chemical attack is minimal. Attempts to replace common clay in a kiln or furnace lining are likely to cause failure soon.

Refractory clay products come in many forms, shaped for different uses:

Pressed bricks: Shaped under high pressure; denser, more uniform.

Shaped (hand-made or machine-formed) bricks: Including special forms for arches, corners, etc.

Insulating firebricks (IFBs): Often lightweight, porous, sometimes made with added pore-formers.

Monolithic forms:

— Castables (unshaped refractory mixes you pour into forms or use to repair)

— Ramming mass (for constructing shapes directly in situ)

— Gunning mixes (sprayed on surfaces to rebuild wear-areas)

Mortars & fire clay cement: Used for laying refractory clay bricks and patching. Fire clay cement often has similar overall composition to the bricks so that joints don’t become weak points.

When purchasing refractory clay bricks or fire clay refractories, you should have the right questions in order to purchase the right material:

Al₂O₃ & SiO₂ content: Understand the amount of alumina and silica required by your temperature and chemical conditions.

PCE / Refractoriness / Softening point: At what temperature will the material begin to deform or become soft?

Porosity and density: Dense materials are more resistant to abrasion; the more porous ones provide insulation. Sometimes you have to have combinations (liner + backup insulation).

Recommended service zone: Suppliers also classify bricks based on where they are supposed to be located in the furnace/kiln (e.g., roof, side, floor, hot face). Failure to use the right zone may make life shorter.

Favorability to slags and alkali: Inquire about compatibility with your process with regard to your process in relation to your process slags, fluxes, or gases. The lab test reports or previous installations of a supplier are beneficial.

Thermal shock and thermal expansion data: For repeated cooling/heating cycles.

Even the best refractory clay bricks eventually degrade. Key things to look out for:

Thermal shock: Sudden temperature changes may cause cracking or spalling.

Chemical attack: Slag, alkali vapors, and acidic or basic fluxes can corrode the material.

Abrasion or mechanical damage: In rotary kilns, sidewalls, or zones where material is in motion.

Wear at joints or mortar lines: Because joints are often weaker points; poor fire clay cement or mortar can cause early failure.

To extend lifespan:

Inspect regularly and replace cracked/damaged bricks early.

Use proper fire clay cement or castables to patch.

Control heating-up and cooling down to avoid thermal shock.

Match refractory type to the service zone (hot face, backup insulation etc.).

Lifespans vary widely. Refractory linings can last decades in a gentler service, but could only be expected to last months or less in very severe service (e.g. acidic slags, very high temperature, frequent cycling).

Refractory clay is an indispensable medium wherever heat, exposure to chemicals and mechanical wear are present. The type selected, be it standard fire clay bricks or high-alumina fire clay refractories, insulating firebrick or specialized monolithic forms, is a big consideration in terms of performance and cost.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected]

|

Mr. RAJESH +91 99130 87000 |

|

Mr. JIGNESH +91 89800 70055 |