Types of Clay Used in Ceramic Industry

03 March, 2026

10 January, 2026

Industrial operations depend heavily on fuel stability and consistent heat output. Industrial coal is specifically processed and graded to meet the performance demands of factories, plants, and large-scale production units.

Coal grades help industries classify coal based on quality parameters such as carbon content, ash, moisture, and calorific value. These grades ensure predictable combustion, better fuel efficiency, and reduced maintenance costs.

With multiple types of coal available in the market, selecting the correct grade is not just a technical decision but a strategic one, especially for sectors like power generation, cement, and metallurgy.

Coal grades refer to standardized classifications that define coal quality and suitability for industrial use. These grades help buyers understand how coal will perform under specific operating conditions.

In India, coal is primarily classified based on GCV ranges, while globally, grading follows ASTM coal classification systems. Coal types in India also vary based on regional mining characteristics, such as lignite from Gujarat/Tamil Nadu or high-GCV bituminous coal imported from Indonesia, Australia, or South Africa.

Industries often differentiate between:

Fuel coal: used for combustion (power, boilers, cement)

Process coal: used for chemical or metallurgical reactions (coking coal, metallurgical coal, foundry coal)

Understanding these classifications helps industries choose the right coal grade for long-term performance and cost effectiveness.

Coal quality standards ensure that industries receive consistent performance and predictable fuel behavior. Several technical parameters determine how suitable a particular coal grade is for industrial use, and each plays a major role in combustion efficiency, heat stability, and operational cost.

Fixed carbon represents the amount of solid combustible carbon available in coal, and it directly influences heat generation. Coal with higher fixed carbon produces stronger, more stable heat, making it essential for foundry coal, metallurgical coal, and other high-temperature applications. Industries involved in metal melting, steel processing, and precision casting rely heavily on consistent fixed-carbon levels to maintain operational accuracy and energy efficiency.

Volatile matter indicates how easily coal ignites and how quickly it burns. Coals with higher volatility ignite faster and help maintain flame stability, which is crucial for boiler coal, industrial furnaces, and kilns. Industries dependent on steam generation or controlled combustion require an optimal volatile matter balance to ensure smooth operation without frequent flame fluctuations or inefficiencies.

Ash is the non-combustible residue left after coal burns, and its percentage greatly affects system maintenance and efficiency. High ash content can cause clinker formation, slag deposits, reduced boiler efficiency, and frequent cleaning requirements. While some industries such as the coal for cement industry can manage moderate ash levels, power plants and boiler-based units prefer low-ash coal to maintain consistent heat flow and avoid operational interruptions caused by residue buildup.

Moisture plays a significant role in determining the heating efficiency of coal. High moisture reduces calorific value, increases transportation weight, and complicates handling during storage and feeding. Lignite coal is known for its high moisture content, which is why it is typically used only by industries located near mining sites, such as local power plants, to reduce transport losses and ensure better fuel performance.

Calorific value, whether measured as GCV or NCV defines how much energy coal can release upon combustion. It directly influences fuel consumption rates, combustion temperature, and overall industrial efficiency. Maintaining proper coal quality standards ensures predictable performance, controlled emissions, stable heat output, and accurate fuel budgeting. For industries like cement, power, metal, or boiler operations, understanding calorific value is essential for selecting the most efficient coal grade for long-term productivity.

Characteristics:

Brownish, moisture-rich coal formed at an early geological stage

Lowest calorific value among coal grades

Soft and easily breakable

Performance Traits:

Quick to ignite but produces low heat

High moisture causes higher fuel consumption

Generates more ash compared to high-grade coal

Industrial Use Cases:

Localized power generation plants near mining sites

Small manufacturing units with low heat demands

Suitable where fuel cost is more important than efficiency

Characteristics:

Moderate calorific value (higher than lignite)

Lower sulfur content makes it more environment-friendly

Better combustion control than lignite

Performance Traits:

Provides stable heat output for continuous industrial operations

More cost-effective than bituminous coal

Lower ash levels reduce operational waste

Industrial Use Cases:

Brick kilns requiring consistent medium-grade heat

Paper and textile mills for steam generation

Industrial boilers operating on medium-temperature ranges

Characteristics:

High energy coal with strong heating capabilities

Lower moisture than lignite and sub-bituminous

Available in multiple grades (thermal coal, steam coal)

Performance Traits:

Offers long and stable combustion cycles

Ideal for high-temperature, high-efficiency processes

Preferred by high-demand industrial sectors

Industrial Use Cases:

Thermal power plants for electricity generation

Cement industry for clinker formation

Boilers and furnaces needing reliable flame consistency

Characteristics:

Highest carbon content (up to 90%)

Shiny, hard, and compact fuel with very low impurities

Premium-grade coal with clean combustion

Performance Traits:

Burns with intense heat and minimal smoke

Produces almost no soot or residue

Long-lasting combustion, ideal for specialized processes

Industrial Use Cases:

Metallurgical industries requiring high furnace temperatures

Water filtration applications

High-value industrial heating and chemical processing operations

Why These Grades Work:

High calorific value ensures higher energy output

Moisture and ash levels are balanced for continuous combustion

Supports efficient turbine and boiler operation

Industry Requirements:

Low sulfur to reduce SO₂ emission

Consistent GCV for predictable power generation

Bulk availability for uninterrupted supply

Why Cement Kilns Need Specific Coal:

Clinker production requires temperatures up to 1450°C

Flame consistency and controlled ash behavior prevent kiln damage

Volatile matter influences flame shape and heat transfer

Industry Requirements:

Moderate ash acceptable since ash goes into clinker

High fixed carbon for strong thermal output

Why These Grades Work:

High carbon content ensures reducing environment needed for ironmaking

Coking coal forms coke, essential for blast furnaces

Low sulfur prevents metal contamination

Industry Requirements:

Strong coke strength and low ash

Controlled volatile matter for furnace stability

Why These Grades Work:

Balanced volatile matter ensures steady steam generation

Low ash prevents scaling and tube blockages

Good heat stability for long boiler cycles

Industry Requirements:

Uniform size (screened coal) for efficient feeding

Consistent GCV to maintain steam pressure

Why Foundries Need Special Coal:

High fixed carbon is essential for molten metal casting

Clean-burning coal avoids impurities in molds

Low sulfur prevents porosity in castings

Industry Requirements:

High calorific value to maintain required furnace temperature

Low ash (<10%) to avoid slag formation in ladles

|

Parameter |

Thermal Coal |

Coking Coal |

|

Purpose |

Heat generation |

Coke production |

|

Used In |

Power plants, boilers |

Steel and metallurgy |

|

Volatile Matter |

Moderate–High |

Low |

|

Fixed Carbon |

Medium |

High |

|

Behavior on Heating |

Burns for heat |

Swells & turns into coke |

Industries must choose based on application rather than price. Thermal coal vs coking coal is always determined by process requirements.

To select the correct grade:

Identify industry heat requirements

Evaluate calorific value and ash limits

Consider sulfur and moisture

Check combustion behavior

Conduct small-batch testing

Ensure compliance with coal quality standards

Choosing the correct coal grade improves efficiency and reduces long-term operational costs.

Some industries face inefficiencies because they:

Choose coal based only on price

Ignore required GCV ranges

Use incorrect types of coal for boilers or furnaces

Overlook ash and moisture content

Skip testing and quality checks

Selecting the wrong grade leads to maintenance issues, reduced output, and higher overall fuel costs.

Coal analysis includes:

Proximate analysis: moisture, ash, volatile matter, fixed carbon

Ultimate analysis: elemental carbon, hydrogen, sulfur

Ensures:

Compliance with coal quality standards

Repeatable performance

Accurate billing and procurement decisions

Testing is essential before bulk purchasing or long-term contracts.

Industries must ensure:

Reduced SO₂ and NOx emissions

Proper ash disposal

Use of low-sulfur and cleaner-burning coal

Compliance with Indian environmental regulations

Better coal selection directly contributes to cleaner and safer industrial operations.

Jay Ganesh Minerals is a reliable and experienced supplier of industrial coal for multiple industries across India. With strong sourcing capabilities and adherence to coal quality standards, the company ensures consistent supply of the right coal grades based on industry requirements.

Expertise in sourcing lignite coal, sub-bituminous, bituminous, metallurgical, and boiler coal

Consistent supply for power plants, cement units, steel factories, and foundry operations

Strong focus on GCV-based and ash-controlled coal supply

Transparent testing, quality assurance, and timely delivery

Capability to fulfill bulk industrial requirements

Jay Ganesh Minerals ensures your industry always receives the right coal grade for optimal performance.

Selecting the right coal grade is crucial for maintaining industrial efficiency, controlling operational costs, and meeting environmental guidelines. Each industry requires different combustion characteristics, making it essential to match coal grades with application needs.

With a trusted supplier like Jay Ganesh Minerals, industries can ensure reliable sourcing, consistent quality, and uninterrupted supply of the best-suited coal grade for smooth and efficient operation.

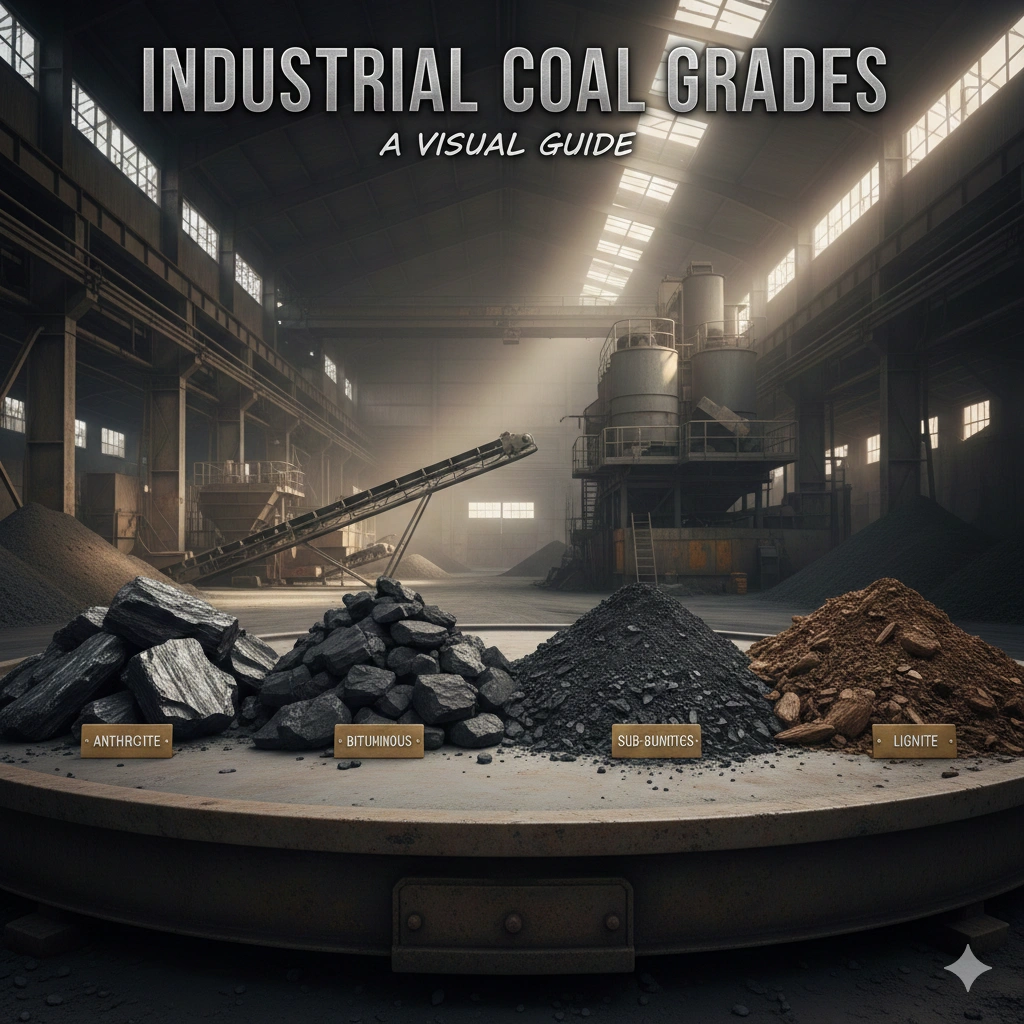

Lignite, sub-bituminous, bituminous, and anthracite are the major industrial coal grades.

Bituminous and sub-bituminous thermal coal are preferred for power generation.

Better-quality coal provides stable heat, lower ash, improved boiler efficiency, and reduced maintenance.

Thermal coal is used for heat generation, while coking coal is used for coke production in steelmaking.

Through supplier verification, proximate analysis, and strict adherence to coal quality standards.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected]

|

Mr. RAJESH +91 99130 87000 |

|

Mr. JIGNESH +91 89800 70055 |