HS Code for Industrial Mineral & Clay: Export - Import Guide

04 February, 2026

02 January, 2026

Plastic clay is one of the most important raw materials used across multiple industries, especially where shaping, molding, and durability are essential. From ceramic manufacturing to construction materials, this versatile material plays a critical role in achieving strength, consistency, and formability.

In industries that depend on precision and quality, plastic clay offers reliable performance due to its excellent workability and binding properties. It is widely preferred in applications involving clay for ceramics, industrial clay formulations, and structural products.

This blog explains what plastic clay is, its composition, characteristics, benefits, and why it remains a preferred choice for ceramic manufacturers and industrial users worldwide.

Plastic clay refers to a type of natural clay that becomes highly moldable when mixed with water. This ability to deform without cracking and retain its shape is known as clay plasticity, which makes it ideal for shaping and forming processes.

Unlike some rigid or coarse clays, plastic clay can be worked easily into complex forms. Its fine particle size and mineral balance give it superior plasticity of clay, making it suitable for both manual and mechanical forming.

Plastic clay is commonly sourced from sedimentary deposits and is often blended with other clay minerals to meet specific industrial requirements.

The performance of plastic clay depends heavily on its clay composition. It typically contains a combination of fine-grained clay minerals such as kaolinite, illite, and sometimes montmorillonite clay in small proportions.

Kaolin clay contributes to whiteness and thermal stability, while other minerals improve binding strength and water retention. The mineral structure allows water molecules to enter between layers, enabling flexibility during shaping.

This balance of clay minerals directly affects workability, shrinkage control, and final product strength.

Plastic clay is known for several essential clay characteristics that make it fit for demanding manufacturing needs:

High plasticity: allows easy forming, bending, and moulding.

Excellent mouldability: works well for manual shaping and machine extrusion, making it an ideal moldable clay.

Strong binding capacity: increases the green (unfired) strength of ceramic and tile bodies.

Smooth texture: ensures uniform shaping and reduces surface defects.

Controlled drying behaviour: although shrinkage exists, good formulation reduces cracks.

Industries rely on various types of clay depending on the application:

Ball clay: highly plastic, commonly used in ceramics, tiles, and sanitaryware.

Fire clay / refractory clay: high-temperature clay with excellent heat resistance.

Stoneware clay: ideal for pottery and industrial ceramics.

Red or earthenware clay: used in bricks, pottery, and construction.

Industrial clay blends: engineered mixtures created for specific firing or shaping requirements.

Plastic clay offers multiple advantages that make it a preferred material for production:

Superior moulding and shaping ability due to its high plasticity clay structure.

Smooth extrusion, ideal for large-scale ceramic and tile lines.

Improves green strength, ensuring the product holds shape before firing.

Better density and strength in the final ceramic or tile body.

Supports complex designs, allowing detailed shaping for artistic and industrial applications.

Reduces production defects, lowering wastage and improving output quality.

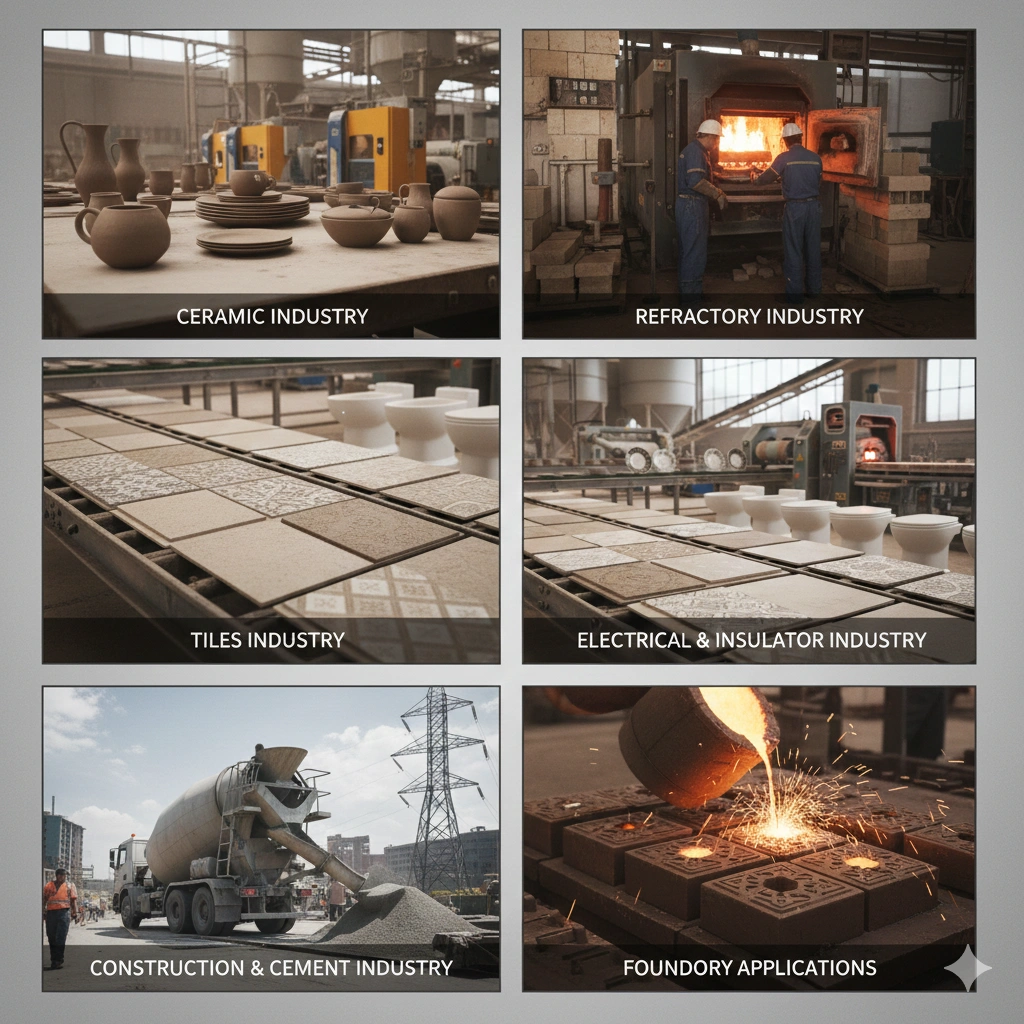

Plastic clay plays a crucial role across multiple industries because of its high plasticity, bonding strength, and excellent shaping behaviour. Below are the major sectors that depend heavily on this versatile industrial clay.

Plastic clay is one of the most important raw materials in clay used in ceramics. Its smooth workability and strength make it suitable for both handcrafted and machine-based ceramic production.

Common ceramic products made using plastic clay include:

Tableware and dinner sets

Porcelain articles

Sanitaryware products

Technical and industrial ceramic components

Its ability to retain shape during forming helps manufacturers achieve precise designs with fewer defects.

The tiles industry relies on industrial clay with high plasticity to ensure stability during shaping and drying.

Plastic clay benefits tile manufacturing by:

Creating uniform wall and floor tile bodies

Enhancing extrusion and pressing performance

Supporting large-volume production of vitrified and ceramic tiles

Its mouldable nature helps maintain consistency in size, texture, and strength.

In the refractory sector, refractory clay (commonly fire clay) is essential for producing high-temperature-resistant products.

Key refractory applications include:

Fire bricks

Kiln furniture

Insulating refractory components

Plastic clay provides heat stability and a strong mineral structure, making it suitable for extreme furnace environments.

Plastic clay is widely used as clay for construction due to its binding and structural properties.

Applications in construction include:

Mortars and plasters

Cement raw mix blending

Structural bricks and blocks

Its adhesive strength improves durability and helps create stable building materials.

High-purity kaolin clay and ball clay are commonly used in electrical and thermal insulators.

Reasons for its use:

Excellent dielectric properties

High heat resistance

Smooth firing behaviour

Plastic clay helps create strong and defect-free insulator bodies for industrial and household applications.

In foundries, plastic clay serves as a natural binder that enhances mould integrity.

Uses in foundry work include:

Binding sand moulds

Improving casting accuracy

Enhancing mould stability

Its superior cohesion ensures precise and reliable casting operations.

Using high-quality plastic clay significantly enhances production efficiency by:

Allowing smoother forming and extrusion in continuous manufacturing lines

Reducing cracking or deformation during drying

Improving moisture control in clay bodies

Reducing overall material wastage

Supporting rapid production cycles for tiles and ceramics

These advantages make it a valuable industrial clay for modern factories.

| Factor | Plastic Clay | Non-Plastic Clay |

|---|---|---|

| Plasticity | High | Low |

| Moulding | Easy | Difficult |

| Shrinkage | Higher | Lower |

| Uses | Ceramics, tiles, sanitaryware | Fillers, construction materials |

| Workability | Smooth | Grainy or stiff |

When selecting plastic clay for tiles, ceramics, or refractories, consider:

Particle size distribution

Moisture level and water absorption

Plasticity index and shaping behaviour

Purity and mineral composition

Firing behaviour and shrinkage

Consistency in supply

Supplier expertise in clay processing and refinement

Jay Ganesh Minerals has established itself as a reliable supplier of industrial clay, serving the ceramic, tiles, and refractory sectors for decades. The company is known for:

Consistent quality and controlled mineral composition

Advanced processing to eliminate impurities

Reliable logistics and bulk delivery

Tailored clay solutions for ceramic and construction industries

Expert knowledge of clay minerals, plasticity, and performance requirements

Their commitment to quality makes them a dependable partner for any manufacturer seeking stable and high-performing plastic clay.

Plastic clay remains one of the most valuable raw materials for ceramic, tiles, refractory, and construction industries. Its high plasticity, strong binding ability, and excellent forming characteristics help manufacturers achieve smooth production and superior finished products. Understanding the types of clay, the role of clay minerals, and the behaviour of high plasticity clay is essential for selecting the right material.

For businesses looking for reliable, high-quality plastic clay and expert guidance, Jay Ganesh Minerals continues to be a trusted supplier supporting industrial growth and innovation.

Clay becomes plastic due to fine particles and water absorption between mineral layers.

Plastic clay is suitable for most ceramic applications, especially when blended with other clays.

Ball clay has higher plasticity but more impurities, while plastic clay offers balanced performance.

Plastic clay can be blended with refractory clay for heat-resistant products.

Ceramics, construction, and industrial manufacturing are the primary users.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected]

|

Mr. RAJESH +91 99130 87000 |

|

Mr. JIGNESH +91 89800 70055 |