Lignite Coal vs Indonesia Coal: Energy, Cost & Uses Compared

04 December, 2025

07 March, 2025

India is a leading name when it comes to premium processed clay. With its rich mineral resources and the advanced processing techniques, the country has developed as a global leader of high quality clay manufacture. While the demand for refined clay in ceramics to cosmetics is booming, India is right at the centre.

Jay Ganesh Minerals is a name which stands for top class clay making process. They have perfect mastery of art of raw clay to an advanced place and have learned how to transform to get highly sought after materials. Jay Ganesh Minerals is the go to supplier for this use whether it’s high end ceramic special formulations or industrial applications.

But why India? It has a natural mineral wealth, skilled labor, and state of the art technology and yet it is the answer that lies hidden in it. The combination of this makes it possible for companies like Jay Ganesh Minerals to process clay and deliver it to global standards, and even more than what the industry expects.

And the demand is high for processed clay for a good reason indeed. It is essential for global industries, from ceramics to cosmetics. The market is booming. In reality, processed clay will demand increase at a rate of 4.5% on an annual basis in the coming years. Being a major supplier, Jay Ganesh Minerals is a leading player in the clay making process.

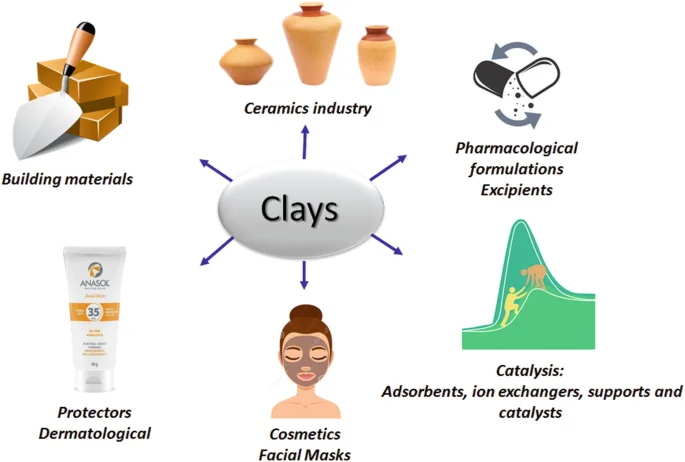

High quality ball clay and kaolin are largely utilized, and they account alone for over 50% of the global clay market where ceramics and construction are the key industries. But it doesn’t stop there. Processed clay has become recognized throughout the world as relevant for use in all kinds of industries including oil drilling and paper production, realizing the versatility of nature’s material for its many uses and unique chemical properties.

With this in mind, a deeper scope for the processed clay is than ever before, as industries continue to ask for higher quality material. With Jay Ganesh Minerals, the world is bought into top tier processed clay that is the exemplar of excellence.

Prominent amongst these is Jay Ganesh Minerals’ assortment of top line, processed clays, which are intended for use under specialized conditions by numerous industries. Their clays are formulated for superior performance and consistency for ceramics, for construction, for drilling and for specialty manufacturing.

1. Ball Clay – Ceramic heart and the pot clay, known for its perfect plasticity, a fine grained structure, and a smooth surface.

2. Kaolin Clay – It forms a substance that is handy for the paper, paint, and rubber industries, providing smooth textures; brightness; and gloss in the sort.

3. Plastic Clay – Mostly characterized as having high plasticity and suitable for ceramics works needing intricate forming and detailing especially for small sized ceramics.

4. WBC Clay – A white-burning clay that has been made for sanitaryware and porcelain with exceptional whiteness and strength.

5. Semi-Plastic Clay – Balances plasticity and strength, good for tiles and other ceramic products that require durability.

6. Processed Clay – Processed clays meeting specific industrial requirements, i.e. which are consistent and of good quality.

7. White Clay – Valued for its purity and whiteness, which is extremely useful in cosmetics, in paper, and in paint industries.

Every product undergoes a painstaking clay making process that yields there has never been such quality, consistency and performance as offered to the industries who require nothing less than best.

Digging up that soil doesn’t mean that clay making is not a process. It’s a laborious process, the transforming of pamid earth, a raw, unrefined earth, into an industrial blockbuster. This is precision engineering at Jay Ganesh Minerals.

Not all of the clay is created equal. The only purists of Ball Clay, Kaolin Clay, China Clay and Bentonite Clay make the cut. India's rich reserves are mined, then each batch is rigorously selected.

The clay is subsequently washed, filtered, and purified in order to remove the impurities. The separation techniques used are high tech techniques that leave behind only the best available material for industry use.

Whether it’s ultra-fine Ball Clay for pottery, high-plasticity Kaolin for paper, or absorbent Bentonite for drilling, the processing is tailored to perfection.

Dried, micronized, and quality-checked, the final product is primed for excellence. That’s how Jay Ganesh Minerals turns raw earth into industrial gold.

Processed clay isn’t just dirt. It’s a powerhouse material shaping industries worldwide, from fine ceramics to heavy-duty drilling. Jay Ganesh Minerals ensures every grain is refined to perfection, making their premium clays a staple in high-performance applications.

From industries demanding strength to those seeking finesse, Jay Ganesh Minerals delivers processed clay that works like magic—no matter where it’s used.

In the world of industrial minerals, processed clay stands as a true game-changer. From ceramics to pharmaceuticals, every industry benefits from its impeccable properties. Jay Ganesh Minerals has proven time and again that they’re the go-to supplier for premium processed clay.

Their dedication to precision in the clay making process sets them apart from the rest. It’s not just about raw materials; it’s about quality control and ensuring every batch is perfect.

For those who demand nothing but the best, Jay Ganesh Minerals delivers. After all, when it comes to premium clay, only excellence will do.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected]

|

Mr. RAJESH +91 99130 87000 |

|

Mr. JIGNESH +91 89800 70055 |