HS Code for Industrial Mineral & Clay: Export - Import Guide

04 February, 2026

05 June, 2025

India’s earth holds much more than land—it’s a blend of many minerals and each one speaks about progress, customs and industry. Semi plastic clay is a valuable material that doesn’t get enough attention.

Because industries are developing at an incredible rate and there is a growing preference for locally sourced raw materials, demand for top-quality semi plastic clay is on the rise. Consistency, pliability and economy are top priorities for ceramic makers, tile factories and companies producing refractory products. Now, let’s turn to semi plastic clay materials. It has exactly what is needed.

At the center of this trend is Jay Ganesh Minerals, a name that is starting to represent the confidence people have in the clay mineral industry. Now, brands that recognize the science of soil are attracting customers,, both in India and elsewhere, from small arts and crafts producers to large-scale goods and services companies.

Semi plastic clay is not simply considered another type of earthy material. It is made of multiple minerals and has medium plasticity, so it’s not too soft but flexible. In short? It behaves.

It is found in the middle range between soft plastic clay and stiff clay. Because of this, engineers often use it for blending and independent experiments in applications that need moderate molding capacity.

It can be any color between light gray and brownish which depends on the minerals in the soil. However, it is primarily valued for keeping structure, drying well and shrinking consistently. Having something predictable gives engineers a huge advantage in industrial processes.

Medium Plasticity: Suitable for precise shaping

High Quality: Limited organic matter and iron oxide present

Less Shrinkage: Fewer visible cracks when water evaporates

Smoothness: Finishing that is free from noticeable lumps

This unique combination is what draws semi plastic clay to be chosen by industries wanting both flexibility and affordability.

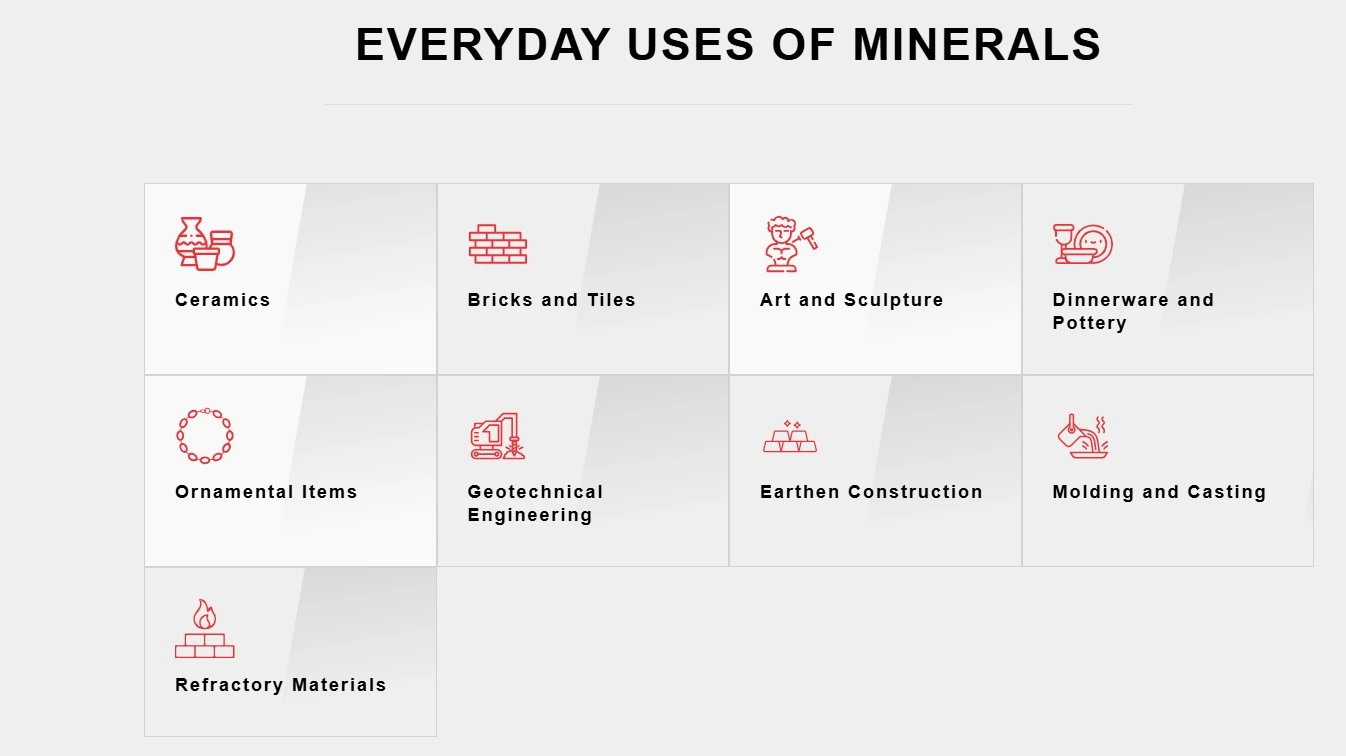

Semi plastic clay really proves its worth by shaping up to match what different industries require—figuratively and literally. Here's how:

From basic bisque ware to intricate pottery forms, ceramic artists love the way semi plastic clay holds shape and fires evenly. Its ability to blend well with ball clay or china clay also makes it an excellent base material.

Used in high-temperature settings, semi plastic clay forms the base of fire bricks and linings. Its consistency ensures that heat doesn’t crack the product during expansion or contraction.

In the tile world, it's often used for backfill or underbody layers. It provides foundational structure without being too brittle or too mushy.

Less common but still important—some formulations of semi plastic clay serve as fillers and texture enhancers in specialty paint and paper products.

Versatile Compatibility: Mixes easily with other clays for custom blends

Thermal Resistance: Withstands high firing temperatures

Consistent Performance: Predictable behavior during shaping, drying, and firing

Lower Production Cost: Offers great performance without premium clay prices

Want to see all technical specs? Explore the complete product breakdown here: semi plastic clay from Jay Ganesh Minerals.

There are clay suppliers, and then there are clay partners. Jay Ganesh Minerals belongs to the latter.

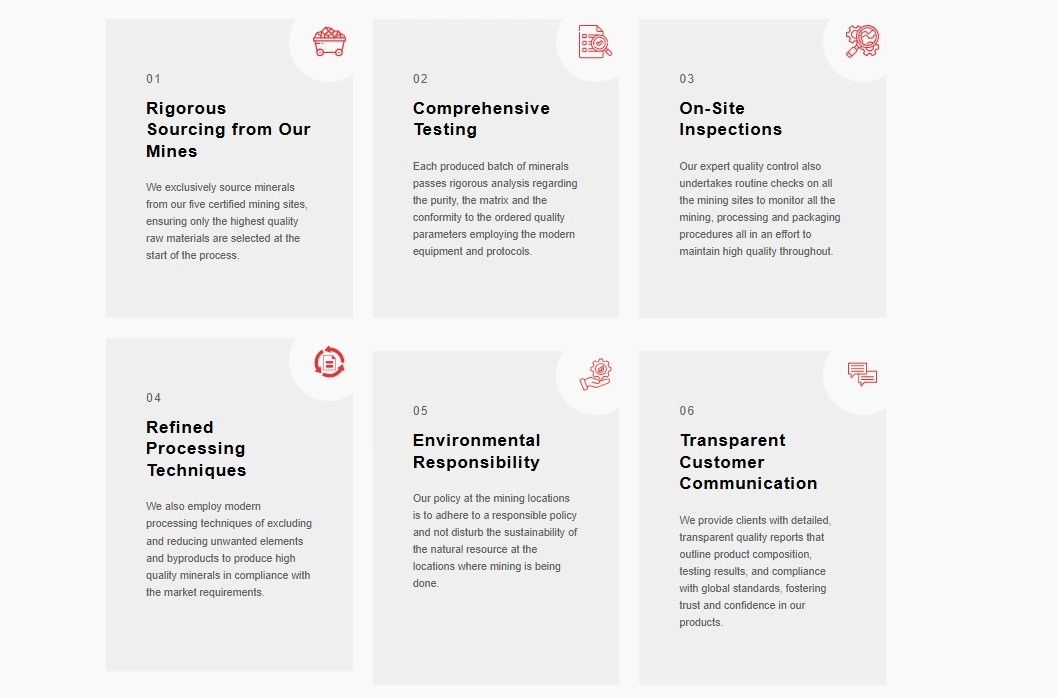

With decades of know-how, they don’t just mine minerals—they engineer solutions. Every batch of semi plastic clay is mined and processed, and refined with stringent quality checks. So what you get isn’t just consistency in texture or tone, but in performance too.

Their strength lies in scale and precision. Whether it’s 1 ton or 100, the product maintains its standard. Clients get clay with optimized granularity, moisture balance, and packaging designed for real-world industrial use.

Another reason they’re an industry favorite? Customization. Not every manufacturer needs the same type of clay. Jay Ganesh Minerals offers tailored blends based on ceramic body formulations, kiln temperatures, and product output expectations.

And in a world leaning toward sustainable sourcing, their environmentally conscious mining practices add one more reason to trust them.

The semi plastic clay market isn’t just growing—it’s evolving. Once confined to local kilns and small-town potters, the material now finds itself in demand across industries and continents.

In India, places like Morbi, Thangadh, and Jaipur are buzzing with demand. Every tile manufacturer, ceramic exporter, and refractory plant is hunting for high-performing clays that deliver under pressure.

Globally, Southeast Asia and the Middle East are two major import hubs for semi plastic clay. Exporters like Jay Ganesh Minerals are capitalizing on this with bulk shipments, strategic warehousing, and on-time delivery guarantees.

There's also a rising segment of DIY enthusiasts and indie pottery brands that have started exploring semi plastic clay for experimental work. With the rise of small-scale ceramic startups, there's now a fresh demand for manageable quantities without compromising on quality.

Add to that the growing awareness around the environmental footprint of industrial inputs, and semi plastic clay’s sustainable sourcing makes it a smart, future-ready choice.

Semi plastic clay might not be glamorous, but it’s quietly critical. It’s the foundational material behind the tiles you walk on, the ceramics you eat from, and the high-temperature bricks that line industrial kilns.

And when it comes to sourcing quality without question, Jay Ganesh Minerals has carved out a position few can match. Their semi plastic clay isn’t just raw material—it’s reliability packed in powdered form.

From its natural composition to its industrial excellence, this mineral is shaping the backbone of multiple sectors.

So whether you’re a large-scale ceramics brand, a pottery enthusiast, or a refractory product maker—if you’re looking for clay that delivers consistency without compromise, it might be time to dig deeper into semi plastic clay.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected]

|

Mr. RAJESH +91 99130 87000 |

|

Mr. JIGNESH +91 89800 70055 |